30

BA081101-en

4.5

Pneumatic Floor Cover

Only for lifts with pneumatic floor cover: Quarterly clean and grease the plastic guides of the

limit stops.

4.6 Cleaning

Do not use high pressure / steam jet cleaners or caustic cleaning agents which attack

coatings and sealing materials. Risk of damage!

Periodically wash off aggressive substances such as salt water, brake fluid etc. and treat the lift

with oil or wax spray.

Repair damage to the paintwork immediately to prevent corrosion.

The RAL number is available through the manufacturer.

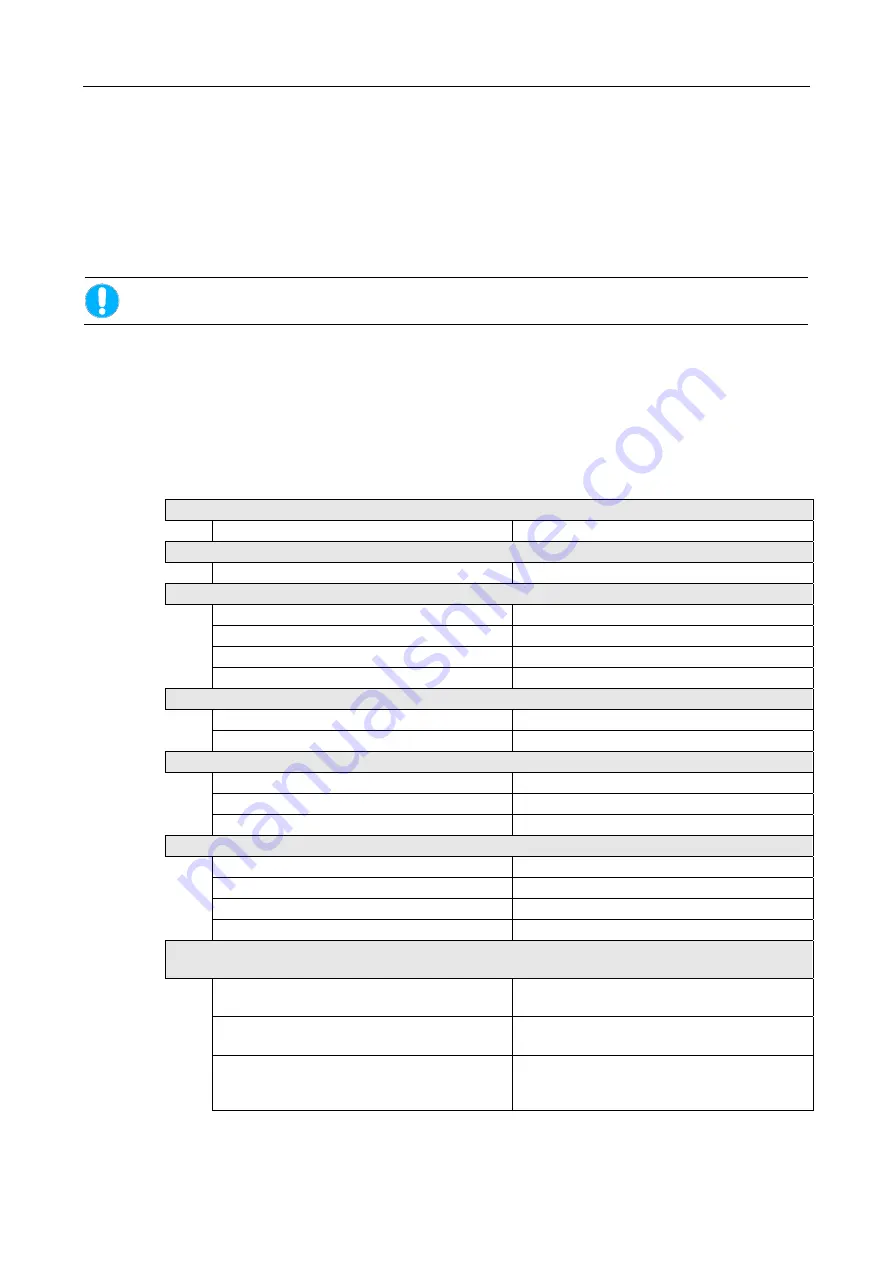

4.7 Troubleshooting

Trouble

Possible Cause

Remedy

Runway lighting does not burn.

Fuse F2 blown.

Replace fuse F2.

POWER signal lamp not burning. Lift does not respond.

Main switch off.

Turn on main switch.

Power fuse blown.

Replace power fuse.

Primary fuse F1 of power pack G1 blown.

Replace fuse F1.

Secondary fuses of power pack G1 blown. Replace fuses.

POWER and ERROR signal lamps burning. Lift does not respond.

Protective motor switch Q2/Q3 off.

Turn on protective motor switch.

Ceiling light barrier B4 dirty.

Cautiously clean light barrier.

POWER signal lamp lighting up, ERROR signal lamp flashing slowly. Lift can be raised only.

Longitudinal LBs triggered by obstacle.

Remove obstacle.

Longitudinal LBs dirty.

Cautiously clean transmitters / receivers.

Longitudinal LBs defective.

Contact service.

POWER signal lamp lighting up, ERROR signal lamp flashing quickly. Lift does not respond.

Transverse LB dirty.

Cautiously clean transmitter / receiver.

Apertures of transverse LB dirty.

Clean apertures (see illustration below).

Transverse LB triggered by obstacle.

Remove obstacle.

Transverse LB defective.

Contact service.

POWER signal lamp lighting up, ERROR signal lamp flashing quickly. Runways unequal in

height, lift does not respond.

Transverse LB triggered by unequal load

distribution on runways.

See section "Runway Synchronization

Check“.

Runways unequal in height despite equal

load distribution. Transverse LB triggered.

See section "Runway Synchron. Check“.

Contact service if required.

Button SET ON LOCKS pressed: Runways

engage different serrations, are unequal in

height. Transverse LB triggered.

See section "Runway Synchronization

Check“.

Summary of Contents for DUO GN Series

Page 8: ...4 BA081101 en...

Page 11: ...BA081101 en 7 Overview of DUO GN Lift with Wheel Free Jack...

Page 14: ...10 BA081101 en...

Page 30: ...26 BA081101 en...

Page 37: ......