31

BA550401-en

6.3

Maintenance by the Operator

The pit jack must be extended to its full height at least 1 x per week and pumped

through a few times with the release spindle closed. This automatically bleeds air

from the system and any accumulated leaked oil is eliminated.

After washing, oil all bright and moving parts.

The ram, the load bearing pivot, rollers and other moving parts must always be

lightly oiled.

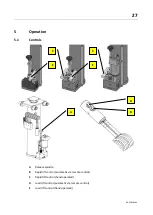

Periodically lubricate the carriage using the lubricator nipples at the rollers (8 pcs).

Underseal residues and other types of dirt can destroy the seals. Clean the piston

rod regularly! Damage to the piston rod must be ground away immediately, ensur-

ing there is a soft transition at the edges. Detergent and salt water can freely pene-

trate and cause considerable damage on the inside.

Water is dangerous! A compressed air service unit, consisting of air filter, water

separator and oil mister, must be present in the compressed air system near to the

lift (max. distance: 5 m). Drain the service unit weekly, check the level of the oil and

that it functions properly. Clean the service unit.

NOTICE

A so-called refrigeration dryer is not adequate as a compressed air service unit! A re-

frigeration dryer cannot filter out the dirt in the line and does not deliver the oil film

necessary for the correct functioning of the equipment.

Failure to observe these rules shall invalidate any guarantee by the manufacturer in

the event of damage caused by rust, dry running and contamination of the pipe-

work.