TWIN F 3.0 A / TWIN F 3.0 U

D1 5002BA1-GB01

22

SLIPPING RISKS

(Ref. Figure 12)

The risk of slipping can be caused by oil or dirt on the floor near the lift

Figure 12 - SLIPPING RISK

!!!!

KEEP THE AREA UNDER AND AROUND THE LIFT CLEAN

.

R

EMOVE ALL OIL

SPILLS

.

ELECTROCUTION RISKS

Avoid use of water, steam, solvent, varnish jets in the lift area where electric cables are

placed and, in particular, next to the electric panel.

RISKS RESULTING FROM IMPROPER LIGHTING

Make sure all areas next to the lift are well and uniformly lit, according to local

regulations.

RISKS OF BREAKING COMPONENT DURING OPERATION

(Ref. Figure 13)

Materials and procedures, suitable for the designed parameters of the lift, have been

used by the manufacturer to build a safe and reliable product. Operate the lift only for

the use it has been designed for and follow the maintenance schedule shown in the

chapter “Maintenance”.

Figure 13 - OBSERVANCE OF TECHNICAL SPECIFICATIONS

Summary of Contents for Twin Series

Page 4: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 II ...

Page 6: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 IV ...

Page 8: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 VI ...

Page 10: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 VIII ...

Page 14: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 4 ...

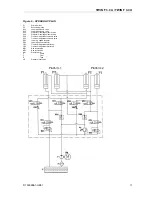

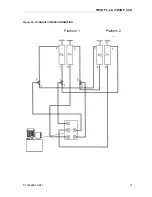

Page 19: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 9 Figure 2 LIFT ...

Page 21: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 11 Figure 3 CONTROL DESK ...

Page 34: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 24 ...

Page 45: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 35 ...

Page 46: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 36 ...

Page 51: ......