TWIN F 3.0 A / TWIN F 3.0 U

D1 5002BA1-GB01

25

7 CHAPTER 7 - INSTALLATION

!!!!

ONLY SKILLED TECHNICIAN

,

APPOINTED BY THE MANUFACTURER

,

OR BY

AUTHORISED DEALERS

,

MUST BE ALLOWED TO CARRY OUT THESE

OPERATIONS

.

SERIOUS DAMAGE TO PEOPLE AND THE LIFT CAN BE CAUSED IF

THEY ARE MADE BY OTHER PERSONS

.

BEFORE CARRYING OUT ANY OPERATIONS

,

REMEMBER TO INSERT THE SAFETY

PIECE OF WOOD BETWEEN THE LOWER BOOMS AND THE BASE FRAME

(R

EF

.

F

IGURE

15)

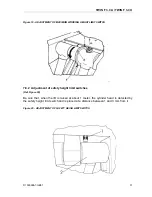

Figure 15 - SAFETY BLOCK

7.1 Preliminary

operations

CHECKING FOR ROOM SUITABILITY

The lift has been designed to be used in covered and sheltered places.

The place of installation must not be next to washing areas, painting workbenches,

solvent or varnish deposits; the installation near to rooms where a dangerous situation

of explosion can occur is strictly forbidden. The relevant standards of the local Health

and Safety at Work regulations, for instance with respect to minimum distance to wall or

other equipment, escapes and the like, shall be observed.

LIGHTING

Lighting must be carried out according to the effective regulations of the place of

installation. All areas next to the lift must be well and uniformly lit.

Summary of Contents for Twin Series

Page 4: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 II ...

Page 6: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 IV ...

Page 8: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 VI ...

Page 10: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 VIII ...

Page 14: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 4 ...

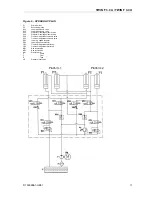

Page 19: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 9 Figure 2 LIFT ...

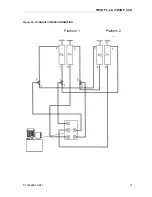

Page 21: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 11 Figure 3 CONTROL DESK ...

Page 34: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 24 ...

Page 45: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 35 ...

Page 46: ...TWIN F 3 0 A TWIN F 3 0 U D1 5002BA1 GB01 36 ...

Page 51: ......