35 Series-HST, Model - 3535, 4035, 4535 & 5035

69

Fuel System

Clean Diesel Fuel

Diesel Fuel should be poured so that no sediment can enter

the tractor fuel tank whilst it is being filled. Fuel storage

facilities should allow for the periodic removal of sediment

from the bottom of the storage tank.

The Diesel fuel filters will remove any sediment still present

in the fuel and ensure that the fuel reaching the injection

pump and injectors is free of impurities. The fuel filter

should be serviced regularly to ensure maximum engine

reliability.

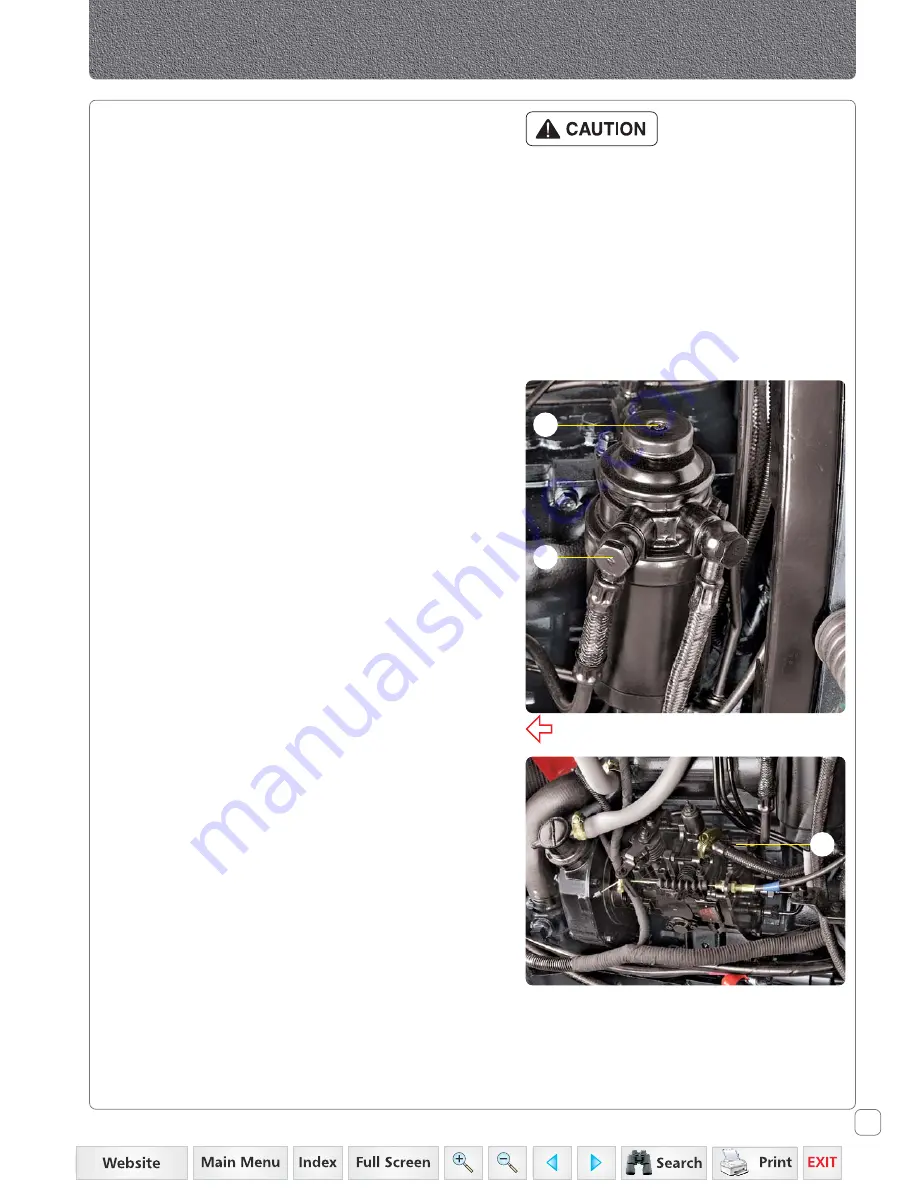

Bleeding the Fuel Filter

The presence of air in the fuel can cause fuel stoppages.

The air should be completely bled so that the machine

operates satisfactorily. Loosen the banjo bolt (B) on FIP side

of filter. Operate hand primer (A) on fuel filter till you get

the flow of fuel free of air from the banjo. Re-tighten the

banjo bolt (B).

Bleeding the Fuel Injection Pump

Loosen the High-Pressure pipes at the nozzle end. Operate

the hand primer (A) on fuel filter till you get a streamline

flow of fuel from the High-Pressure pipes. Retighten the

High-Pressure pipes and start the engine. Observe till the

engine runs smoothly and then shut-off till further use.

Fuel Tank and Fuel Pipes

Fill the tank each time the tractor finishes the days work.

This prevents condensation inside the fuel tank. Check

regularly to ensure all fuel pipe unions are tight and in

good order. Ensure that vent hole provided on fuel tank cap

is not choked. Water or dirt settled in the bottom of fuel

tank should be drained daily, before starting the engine by

loosening the drain cock till clean diesel flows.

Tamper Proofing

Calibration of Fuel Injection Pump plays a vital role in

Engine performance and hence the same shall not be

disturbed by unauthorised persons.

In order to prevent tampering, a tamper-proof arrangement

is provided on Fuel Injection Pump consisting of SPECIAL

SEALS (C). Any FIP related work should be carried at

Mahindra / BOSCH authorised dealership.

Escaping hydraulic diesel fluid under pressure

can penetrate the skin causing serious injury.

Do not use your hand to check for leaks. Use

piece of cardboard or paper to search for leaks.

Stop engine and relieve pressure before

connecting or disconnecting lines.

Tighten all connections before pressurizing

lines.

If any fluid is injected into the skin obtain

medical attention immediately or else, serious

injury may result.

Tractor Front

B

C

A

Summary of Contents for 3535

Page 1: ...OPERATOR S MANUAL 35 Series 4WD 3535 4035 4535 5035 HST ...

Page 9: ...35 Series HST Model 3535 4035 4535 5035 ...

Page 13: ...35 Series HST Model 3535 4035 4535 5035 ...

Page 25: ...35 Series HST Model 3535 4035 4535 5035 24 Safety Signs ...

Page 26: ...35 Series HST Model 3535 4035 4535 5035 25 Safety Signs ...

Page 27: ...35 Series HST Model 3535 4035 4535 5035 26 Safety Signs ...

Page 28: ...35 Series HST Model 3535 4035 4535 5035 27 Safety Signs ...

Page 108: ...107 35 Series 4WD HST Model 3535 4035 4535 5035 Wiring Diagram 35 Series HST ...