TROUBLE SHOOTING CAUSES & REMEDIES

Trouble noticed

Problem caused & solution

1. Dozer not functioning

2. Dozer upward movement very slow and

unable to lift with load.

3. Dozer not lifting.

4. Dozer coming down immediately from top

position.

5. Bucket not loading or bucket loaded

comes down & material falls.

6. Hydraulic cylinder not functioning (or) oil

leaking

7. Air sound noticed while operation

8. Rear tyre slips during loading

9.Joystick struck not going to the float

position

10. Oil heats up rapidly within few minutes.

1. Insufficient oil in the reservoir.

If less add oil.

2. Oil is not pumped. Check using pressure

check port of the valve pressure should be

140 BAR.

1. Check piston oil seal &replace it required.

2. Check pump pressure &replace it required.

1. Piston oil seal & arm cylinder damaged.

Replace the same.

2. Pump problem, Check pump pressure.

1. Piston seal of arm cylinder damaged.

Replace the same.

2. Pump problem, Check pump pressure.

1. Piston seal of bucket cylinder damage,

Replace the same the part.

2. Pump problem, Check pump pressure.

Send the same to your authorized service

station or to the company for rectification.

Insufficient oil fills in the tank.

1. Water ballasts the rear wheels.

2. Increase the weight in the rear weight

carrier.

3. Mount cast iron ballast in the rear tyre.

4. Rotate the bucket upwards the moment the

tyre slips.

Remove the bottom plastic cap of the valve,

adjust the screw.

Summary of Contents for AppliTrac

Page 5: ...MOUNTING INSTRUCTIONS...

Page 6: ...CONNECTING THE HYDRAULIC SYSTEM...

Page 11: ...TROUBLE SHOOTING CAUSES REMEDIES...

Page 12: ...NIPPLE FOR PRESSURE TESTING GAUGE SHOWING...

Page 15: ...MAINTENANCE...

Page 18: ...Dozer Spare Parts Catalogue...

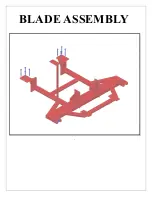

Page 19: ...DOZER ASSEMBLY...

Page 20: ...CHASSIS ASSEMBLY...

Page 21: ...HYD MTG ASSEMBLY...

Page 22: ...FRAME ASSEMBLY...

Page 23: ...BLADE ASSEMBLY...