OPERATING TIPS

It is best to spend a few minutes analyzing the job at the work area.

Set up the work cycle as short as possible less movement leads to the shorted work

cycle that will improve work efficiency.

When the Dozer is used in a specific area mark layout for parking the lorry and put a

ramp with stopper for the tractor to operate with maximum efficiency.

LOADING LOOSE MATERIAL

a)

Make sure the bottom of the bucket is in level with the ground.

b)

Make use of bucket level indicator provided.

c)

Move Dozer control lever to float position and move the machine forward to the pile.

d)

When the machine starts to slower, lift the bucket and roll it back.

e)

If trained driver is not operating the rear wheel slippage may take place. The rear

wheel slippage can be stopped only by better driving methods. When the rear wheel starts

slipping, the moment the bucket must be rolled back just adequately. Then again tractor can

be moved forward after loading some volume of material again the wheels will try to slip.

Now the bucket is also to be rolled back adequately. This process is to be repeated 3 to 4

times before loading the bucket fully.

Summary of Contents for AppliTrac

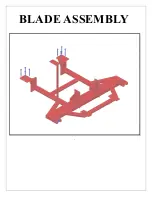

Page 5: ...MOUNTING INSTRUCTIONS...

Page 6: ...CONNECTING THE HYDRAULIC SYSTEM...

Page 11: ...TROUBLE SHOOTING CAUSES REMEDIES...

Page 12: ...NIPPLE FOR PRESSURE TESTING GAUGE SHOWING...

Page 15: ...MAINTENANCE...

Page 18: ...Dozer Spare Parts Catalogue...

Page 19: ...DOZER ASSEMBLY...

Page 20: ...CHASSIS ASSEMBLY...

Page 21: ...HYD MTG ASSEMBLY...

Page 22: ...FRAME ASSEMBLY...

Page 23: ...BLADE ASSEMBLY...