19

Chapter

Ⅲ

Technical Maintenance of the Tractor

In order to keep the tractor in excellent condition, prolong its service life and reduce

troubles, the users must often check the technical conditions of the tractor and strictly carry

out technical maintenance of all classes.

Table 3-1 Technical Maintenance Periodic Table

In actual use, users can add and perfect the contents and methods of maintenance

according to concrete conditions.

1. Shift maintenance

1) Clean dirt and sludge on the tractor and implements. Under the extremely dusty

circumstances, the air filter should be cleaned.

2) Check all main fastening bolts and nuts on the tractor outside, especially whether

front and rear wheel nuts are loose, tighten if necessary.

3) Examine the liquid level in oil sump, radiator, fuel tank and lifter; refill if necessary.

Only after the engine has stopped for more than 15 minutes can the oil lever in oil sump be

examined.

4) Check whether there is leakage of oil, water and air; remove if necessary.

5) Check the tire pressure, and inflate if necessary.

6) Grease the points according to the table 2-1. Before greasing, the sludge and water

should be squeezed from the lubricating points.

7) Check the specified tools supplied.

2. First class maintenance

Carry out the following maintenance after every 50 hours of operation:

1) Carry out the maintenance items in shift maintenance.

2) Clean air filter, and replace oil in the filter house.

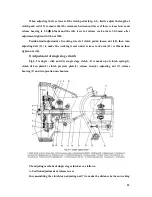

3) Check the fan belt tension (When pressing the middle part of the longer side of the

belt, the belt drops about 15-25 mm under the force of about 10N, then the tension is

suitable), adjust if necessary.

4) Check and adjust the free travels of clutch pedal and brake pedals.

Maintenance class

Working hours of the tractor (h)

Shift maintenance

After every shift or every 10-12 hours of operation

First class maintenance

Every 50 hours of operation

Second class maintenance

Every 250 hours of operation

Third class maintenance

Every 500 hours of operation

Fourth class maintenance

Every 1000 hours of operation

Summary of Contents for JINMA-200

Page 14: ...9 Fig 2 1 Controls and Instruments ...

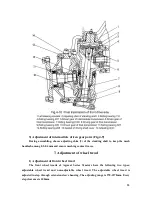

Page 41: ...36 ...

Page 47: ...42 ...

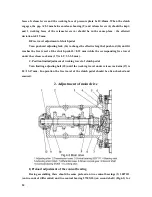

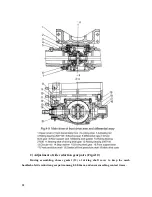

Page 66: ...61 3 Distribution diagram of rolling bearing and transmission system of Jm series tractors ...

Page 67: ...62 ...

Page 71: ...66 ...