20

5) Check the oil level in transmission box and front drive axle, refill if necessary.

6) Wipe the battery with a piece of cloth, check the electrolyte level which should be 10-

15 mm above the polar plates, refill with distilled if necessary . Smear the terminals with

grease to avoid corrosion.

3. Second class maintenance

Carry out the following maintenance after every 250 hours of operation;

1) Complete first class maintenance items.

2) Replace the engine oil in engine sump, flush engine sump, oil pump strainer and oil

filter.

4. Third class maintenance

Carry out the following maintenance after every 500 hours of operation.

1) Complete second class maintenance items.

2) Check and adjust inlet and exhaust valve clearance, injection pressure and spray

atomization of the injector according to the requirements in the engine operation manual.

3) Clean fuel tank and fuel cartridge.

4) Flush transmission box, replace lubricating oil.

5) Flush the filter of hydraulic lifter, check the oil cleanliness degree, flush the inside of

lifter house and replace with fresh oil if necessary.

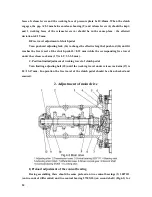

6) Check and adjust front wheel toe- in (The toe - in should be 4-10 mm). Check the

clearance of the front wheel bearing, and adjust if necessary. Replace the grease in the front

wheel hubs.

°

7) Check the free travel of the steering wheel (The free angle should be less than 15

),

adjust if necessary.

8) Check the oil level in steering gear, and refill if necessary.

5. Fourth class maintenance

Carry out the following maintenance after every 1000 hours of operation;

1) Complete third class maintenance.

2) Carry out maintenance items according to regulations in diesel engine operation

manual.

3) Clean the fuel tank with 25% hydrochloric acid solution, then flush it with clean

water.

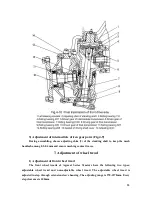

4) Disassemble the starter and generator, clean off the grease in the bearings and

replace it with fresh grease. Meanwhile examine the transmission mechanism of the starter.

5) Clean the gathered carbon in the silencer and exhaust manifold.

6) Immerse the front bearing and release bearing of the clutch into dissolved high

temperature- resistant grease, and refill with fresh grease.

Summary of Contents for JINMA-200

Page 14: ...9 Fig 2 1 Controls and Instruments ...

Page 41: ...36 ...

Page 47: ...42 ...

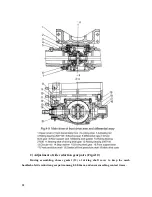

Page 66: ...61 3 Distribution diagram of rolling bearing and transmission system of Jm series tractors ...

Page 67: ...62 ...

Page 71: ...66 ...