27

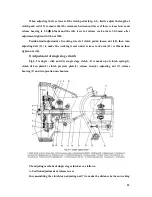

c. Adjustment of mesh backlash and mesh print

During adjustment, the bevel gear and pinion axially moving will change both mesh

backlash and mesh print. If the mesh print requirement is contradictory to mesh backlash,

correct mesh print should mainly be ensured, and the adjustment range of mesh backlash can

be enlarged (Especially when the gear and bearing wears and the readjustment is needed, the

backlash can be enlarged). But the mesh backlash should be not less than 0.1mm.

During normal operation of the tractor, the normal mesh backlash and mesh point will

both change, under this condition, so long as teeth faces contact is normal, only the mesh

backlash increases, and this increase of backlash due to gear wear need not be adjusted. But

after the overhaul of the tractor or when replacing a new pair of main drive gears or bevel

bearing, the mesh print and backlash should be ensured at the same time by careful

adjustment.

Note: As the bevel pinion and the bevel gear are a pair of matched gears, be sure not to

make pairs in disorder. The spiral bevel gears should be replaced together with the bearings,

if possible. Otherwise, it will affect their service life.

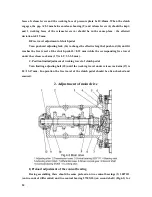

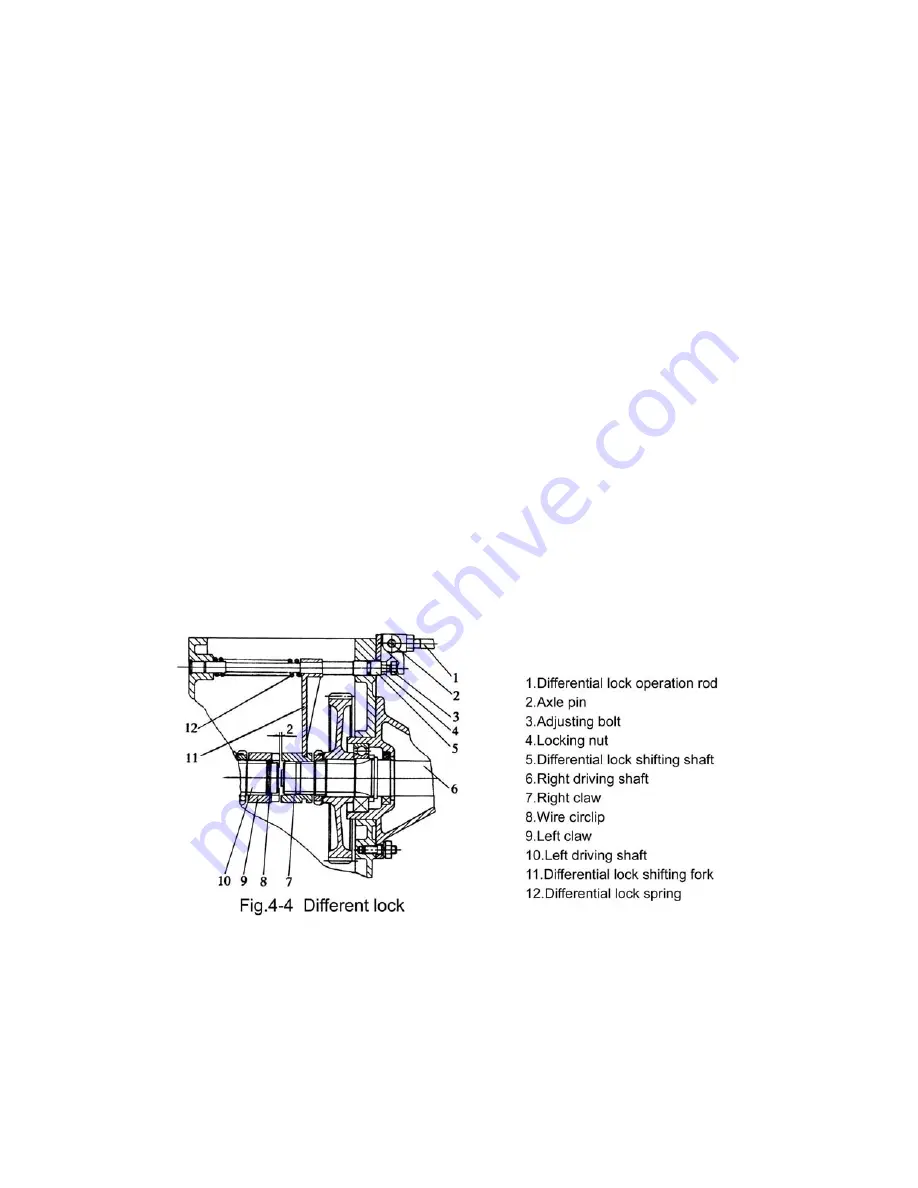

3. Adjustment of differential lock

The differential lock can be adjusted through bolt (3) and nut (4). During adjusting,

the gap between left claw (9) and right claw (7) should be about 2mm. Screw in or out the bolt

(3) to increase or reduce the gap. After the adjustment has been done, use nut (4) to tighten

bolt (3). (Fig.4-4)

Summary of Contents for JINMA-200

Page 14: ...9 Fig 2 1 Controls and Instruments ...

Page 41: ...36 ...

Page 47: ...42 ...

Page 66: ...61 3 Distribution diagram of rolling bearing and transmission system of Jm series tractors ...

Page 67: ...62 ...

Page 71: ...66 ...