TYRE MAINTENANCE

MAINTENANCE

21

Checking tyre pressure

For normal load and operation of the tractor the following tyre pressure is recommended

Note :

1. Keep the tube valve always closed with the dust cap, to protect

the valve from mud/dust/slush.

2. To achieve best performance and maximum tyre life, maintain

air pressure as per tyre size and load carrying capacity as recommendation.

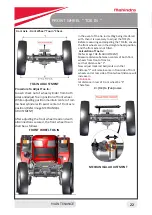

Addition of Wheel Weights At Rear – To increase drawbar pull of the tractor &

reduce wheel slip (Increase tyre life)

Cast Iron weights can be attached to the rear driving wheels.

In case the slip continues, it may be necessary to liquid ballast the tyre.

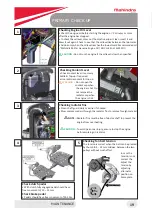

Adding Water :

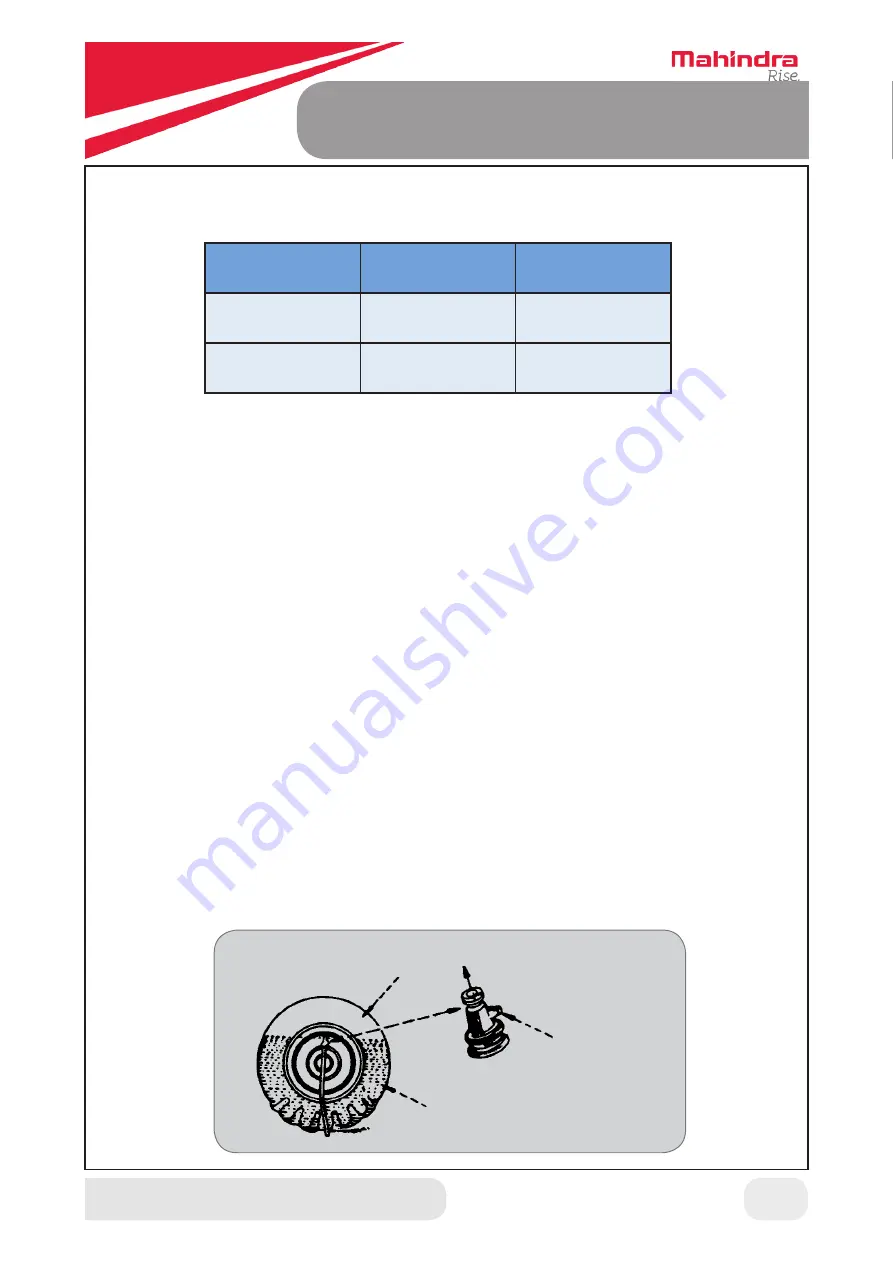

Tractor tyre can be 80% filled with water as follows, Remove excess air from Tyre.

1. Remove all air from tyre.

2. Raise the wheel. Rotate the tyre until the valve, stem is at 1’O Clock position.

3. Remove the valve core housing and screw on the adapter.

4. Force water into the tyre from a tank placed at least five feet higher than the tractor tyre, or by

using a compressor and pressure tank filled with water.

5. When the liquid has reached the required level, remove the adapter, screw in the valve core

and inflate to the recommended pressure.

6. Maintain air pressure as per recommendation

The instructions and recommendation shown below should be followed in order to secure maxi

-

mum life and efficient service from pneumatic tyres.

Front tyre

6 x 14”

Rear tyres

8.3 x 24”

For field

1.3 kg/cm²

1.2 kg/cm²

For road

2.0 kg/cm²

1.4 kg/cm²

Liquid

Bleeder

To Valve

Air

Adaptor or Hose connection

Summary of Contents for Jivo 245 DI

Page 1: ...SERVICE MANUAL...

Page 4: ...GENERAL...

Page 6: ...PRODUCT SPECIFICATION GENERAL 6...

Page 8: ...MAINTENANCE...

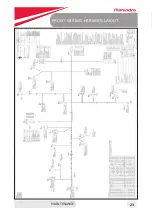

Page 23: ...FRONT WIRING HARNESS LAYOUT MAINTENANCE 23...

Page 24: ...REAR WIRING HARNESS LAYOUT MAINTENANCE 24...

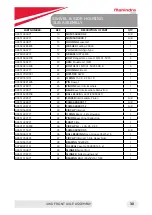

Page 25: ...4WD FRONT AXLE ASSEMBLY...

Page 26: ...BEARING OIL SEAL POSITION 4WD FRONT AXLE TORQUE VALUES 4WD FRONT AXLE ASSEMBLY 26...

Page 28: ...4WD FRONT AXLE OIL GREASE SPECIFICATIONS MAINTENANCE 28...

Page 42: ...TRANSMISSION...

Page 43: ...BEARING OIL SEAL POSITIONS TRANSMISSION TORQUE VALUES TRANSMISSION MAIN LINE ASSEMBLY 43...

Page 44: ...TRANSMISSION OIL AND GREASE SPECIFICATIONS TRANSMISSION MAIN LINE ASSEMBLY 44...

Page 69: ...ENGINE...

Page 70: ...DETAILED ENGINE SPECIFICATIONS ENGINE ASSEMBLY 70...