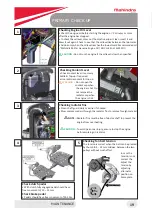

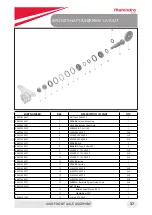

HUB END -ASSEMBLY PROCESS

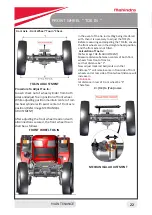

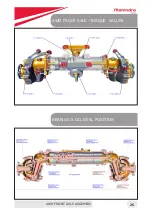

4WD FRONT AXLE ASSEMBLY

1

5

Assemble the Cas-

sette Seal (5) with

hub Housing (6)

with the help of

suitable special

purpose

dolly.

Assemble the final

Reduction bevel

gear (10) to Spin

-

dle Front axle (3)

Assemble the

Bearing 35X72X17

(8) in Hub Hous

-

ing (6) after fit

-

ment of seal

A s s e m b l e

the

Bearing

30X62X16

(11)

in Spindle with

suitable

dolly

Assemble the

Spindle

Front

Axle (3) in Hub

Housing

(6)

Fitment of collar

(14) to Spindle

Groove (3)

For cassette oil seal, maximum internal float

recommended is 0.30 mm. Hence SHIM (7) se

-

lection is required to control it within 0.20

mm (if more, the lip of the oil seal will invert).

Calculation must be done when Spindle or hub

housing is replaced. It should also be done

when early hour oil seal leakage is observed.

For Example-

reading = 0.32 mm

Recommended maximum float = 0.20 mm

SHIM = 0.32 – 0.20 = 0.12 mm

Spindle Play should be max. 0.20mm

2

6

7

3

4

Fitment of O-Ring

(12) to Hub Hous

-

ing

Ensure free rotation of bearing rollers

after assembly

Assembly should be free from dust and

foreign particles

Apply grease during assembly of oil seal

only

⚠

NOTE:-

3

1

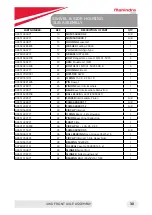

HUB END ASSEMBLY CRITICAL SETTINGS

1

Summary of Contents for Jivo 245 DI

Page 1: ...SERVICE MANUAL...

Page 4: ...GENERAL...

Page 6: ...PRODUCT SPECIFICATION GENERAL 6...

Page 8: ...MAINTENANCE...

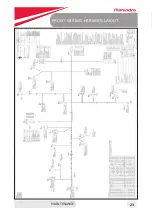

Page 23: ...FRONT WIRING HARNESS LAYOUT MAINTENANCE 23...

Page 24: ...REAR WIRING HARNESS LAYOUT MAINTENANCE 24...

Page 25: ...4WD FRONT AXLE ASSEMBLY...

Page 26: ...BEARING OIL SEAL POSITION 4WD FRONT AXLE TORQUE VALUES 4WD FRONT AXLE ASSEMBLY 26...

Page 28: ...4WD FRONT AXLE OIL GREASE SPECIFICATIONS MAINTENANCE 28...

Page 42: ...TRANSMISSION...

Page 43: ...BEARING OIL SEAL POSITIONS TRANSMISSION TORQUE VALUES TRANSMISSION MAIN LINE ASSEMBLY 43...

Page 44: ...TRANSMISSION OIL AND GREASE SPECIFICATIONS TRANSMISSION MAIN LINE ASSEMBLY 44...

Page 69: ...ENGINE...

Page 70: ...DETAILED ENGINE SPECIFICATIONS ENGINE ASSEMBLY 70...