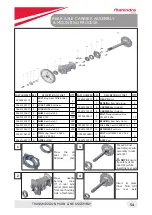

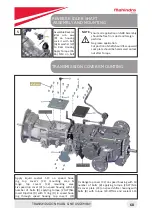

REVERSE IDLER SHAFT

ASSEMBLY AND MOUNTING

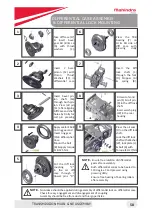

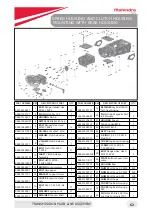

TRANSMISSION MAIN LINE ASSEMBLY

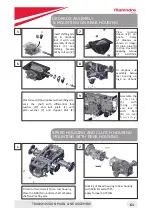

TRANSMISSION COVERS MOUNTING

Assemble Reverse

idler sub assy

(R) on housing

Lock it with bolt

(G) & washer (W)

to Rear Housing

Apply Torque (55-

65) NM on bolt

5

Ensure oil application on NRB Assembly

should be free from dust and foreign

particles

No grease application.

Cut portion of shaft should face upward

Lock plate should be hammered on lock

nut after Torque

⚠

NOTE:-

Apply liquid sealant 515 on speed hous-

ing top cover’s (C1) mounting area &

range top cover’s (C2) mounting area.

Fix speed top cover (C1) on speed housing with 12

number of bolts (B) applying torque (20-27)Nm.

Insert Dipstick (D) with O ring (O) in speed hous

-

ing through speed housing top cover’s (C1)

Fix Range top cover (C2) on speed housing with 10

number of bolts (B) applying torque (20-27)Nm.

Fix cover plate (C3) on speed shifter housing with

bolts (B) with torque (20-27)Nm and sealant 515

68

Summary of Contents for Jivo 245 DI

Page 1: ...SERVICE MANUAL...

Page 4: ...GENERAL...

Page 6: ...PRODUCT SPECIFICATION GENERAL 6...

Page 8: ...MAINTENANCE...

Page 23: ...FRONT WIRING HARNESS LAYOUT MAINTENANCE 23...

Page 24: ...REAR WIRING HARNESS LAYOUT MAINTENANCE 24...

Page 25: ...4WD FRONT AXLE ASSEMBLY...

Page 26: ...BEARING OIL SEAL POSITION 4WD FRONT AXLE TORQUE VALUES 4WD FRONT AXLE ASSEMBLY 26...

Page 28: ...4WD FRONT AXLE OIL GREASE SPECIFICATIONS MAINTENANCE 28...

Page 42: ...TRANSMISSION...

Page 43: ...BEARING OIL SEAL POSITIONS TRANSMISSION TORQUE VALUES TRANSMISSION MAIN LINE ASSEMBLY 43...

Page 44: ...TRANSMISSION OIL AND GREASE SPECIFICATIONS TRANSMISSION MAIN LINE ASSEMBLY 44...

Page 69: ...ENGINE...

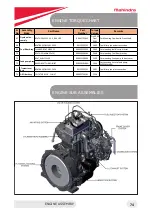

Page 70: ...DETAILED ENGINE SPECIFICATIONS ENGINE ASSEMBLY 70...