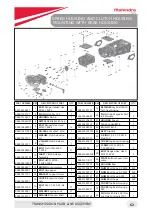

RECOMMENDED FIP

MOUNTING INSTRUCTION

ENGINE ASSEMBLY

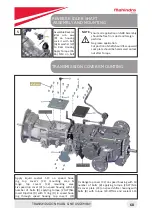

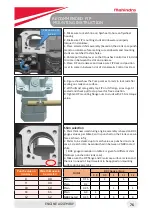

Shim selection

1. Shim thickness used during engine assembly is based on BDC

gauge value as per table 2 and is punched on the Crank case sur-

face as shown in fig

2. Shims to be stacked up to match value as punched on crank

case, 1 steel shim to be sandwiched in between 2 NBR coated

shim.

( BDC gauge dimension in table 2 is given for different shim

thickness punched on crank case) .

3. Make sure the FIP flange and Crank case surface is clean and

there is no need of liquid sealant to be applied on mounting

surface during assembly .

Punch value on

crankcase

Shim thickness to

be selected

8

0.8

9

0.9

10

1.0

11

1.1

12

1.2

SHIMS

BDC Gauge Value

0.8

0.9

1

1.1

1.2

Plain

0.15

1

1

Plain

0.2

Plain

0.25

1

1

Plain

0.3

1

NBR Coated

0.25

2

3

3

4

4

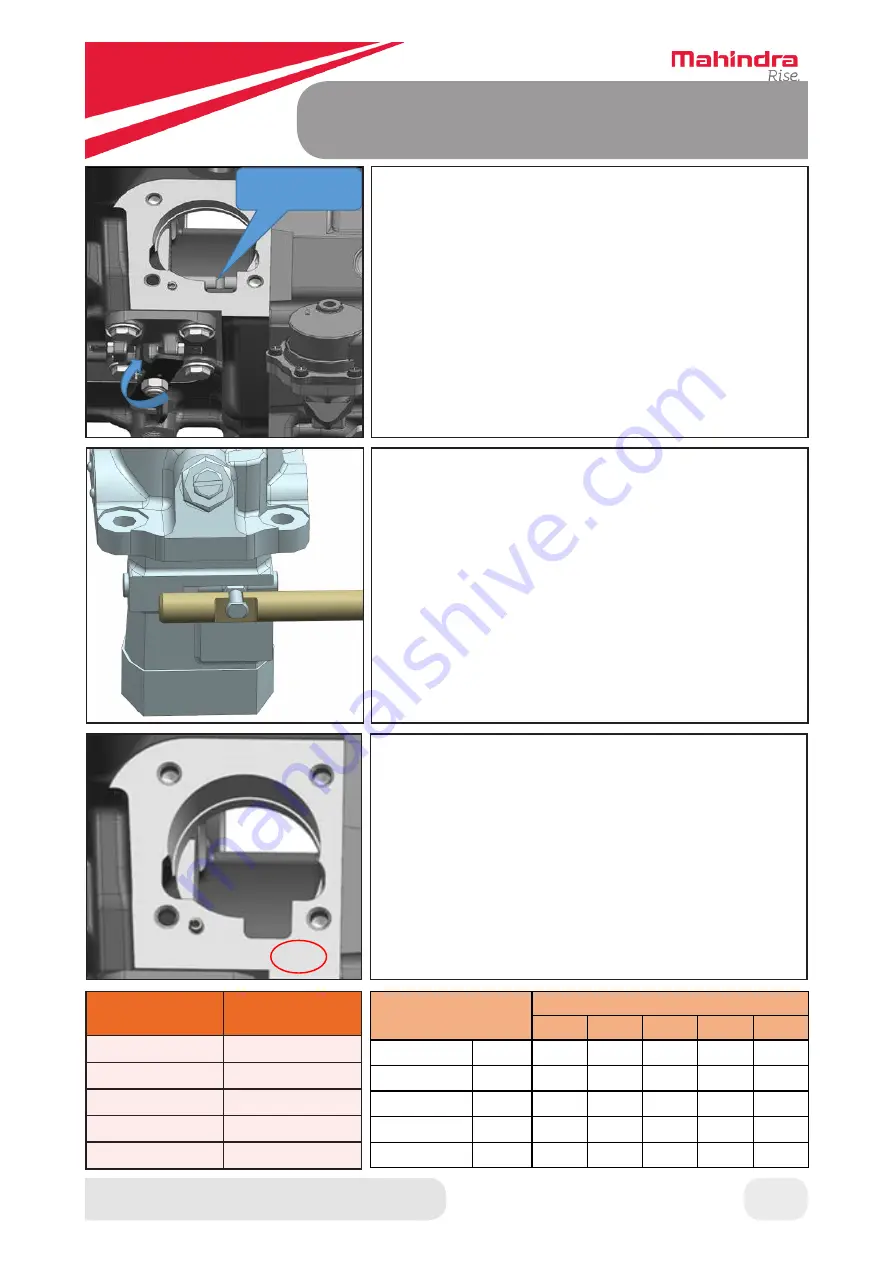

Slot on control

rack rod

1. Make sure to match line on flywheel to hole on flywheel

housing

2. Make sure FIP mounting studs and dowel are properly

torqued in crankcase,

3. Place selected shim assembly (based on the crank case punch

mark) on crankcase face making sure all dowels and mounting

studs are matched to shim holes.

4. Rotate pull to stop lever so that it pushes Control rack rod slot

to come in between the slot on crankcase.

5. Place FIP on crankcase and make sure FIP Rack rod position

is set to come in between slot of crankcase & Control rack rod.

6. Figure shows how the Pump comes to rests in rack rod after

seating on crank case surface .

7. With utmost care gently tap FIP on its flange, so as to get it

seated and check pull to stop lever for free actuation.

8. Tighten FIP mounting flange nuts to studs with 25 Nm torque

value.

76

Summary of Contents for Jivo 245 DI

Page 1: ...SERVICE MANUAL...

Page 4: ...GENERAL...

Page 6: ...PRODUCT SPECIFICATION GENERAL 6...

Page 8: ...MAINTENANCE...

Page 23: ...FRONT WIRING HARNESS LAYOUT MAINTENANCE 23...

Page 24: ...REAR WIRING HARNESS LAYOUT MAINTENANCE 24...

Page 25: ...4WD FRONT AXLE ASSEMBLY...

Page 26: ...BEARING OIL SEAL POSITION 4WD FRONT AXLE TORQUE VALUES 4WD FRONT AXLE ASSEMBLY 26...

Page 28: ...4WD FRONT AXLE OIL GREASE SPECIFICATIONS MAINTENANCE 28...

Page 42: ...TRANSMISSION...

Page 43: ...BEARING OIL SEAL POSITIONS TRANSMISSION TORQUE VALUES TRANSMISSION MAIN LINE ASSEMBLY 43...

Page 44: ...TRANSMISSION OIL AND GREASE SPECIFICATIONS TRANSMISSION MAIN LINE ASSEMBLY 44...

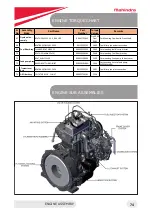

Page 69: ...ENGINE...

Page 70: ...DETAILED ENGINE SPECIFICATIONS ENGINE ASSEMBLY 70...