22

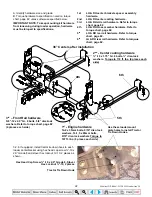

A. Identify hardware size and grade.

B. Torque hardware to specification noted on torque

chart, page 82, unless otherwise specified below.

IMPORTANT NOTE: To keep mounting kit hardware

from loosening during loader operation, hardware

must be torqued to specifications.

1st

LH & RH center brackets spacer assembly

hardware.

2nd

LH & RH center casting hardware.

3rd

LH & RH side rail hardware. Refer to torque

chart, page 82.

4th

LH & RH cross member hardware. Refer to

torque chart, page 82.

5

th

LH & RH rear rail hardware. Refer to torque

chart, page 82.

6

th

LH & RH rear rail hardware. Refer to torqwue

chart, page 82.

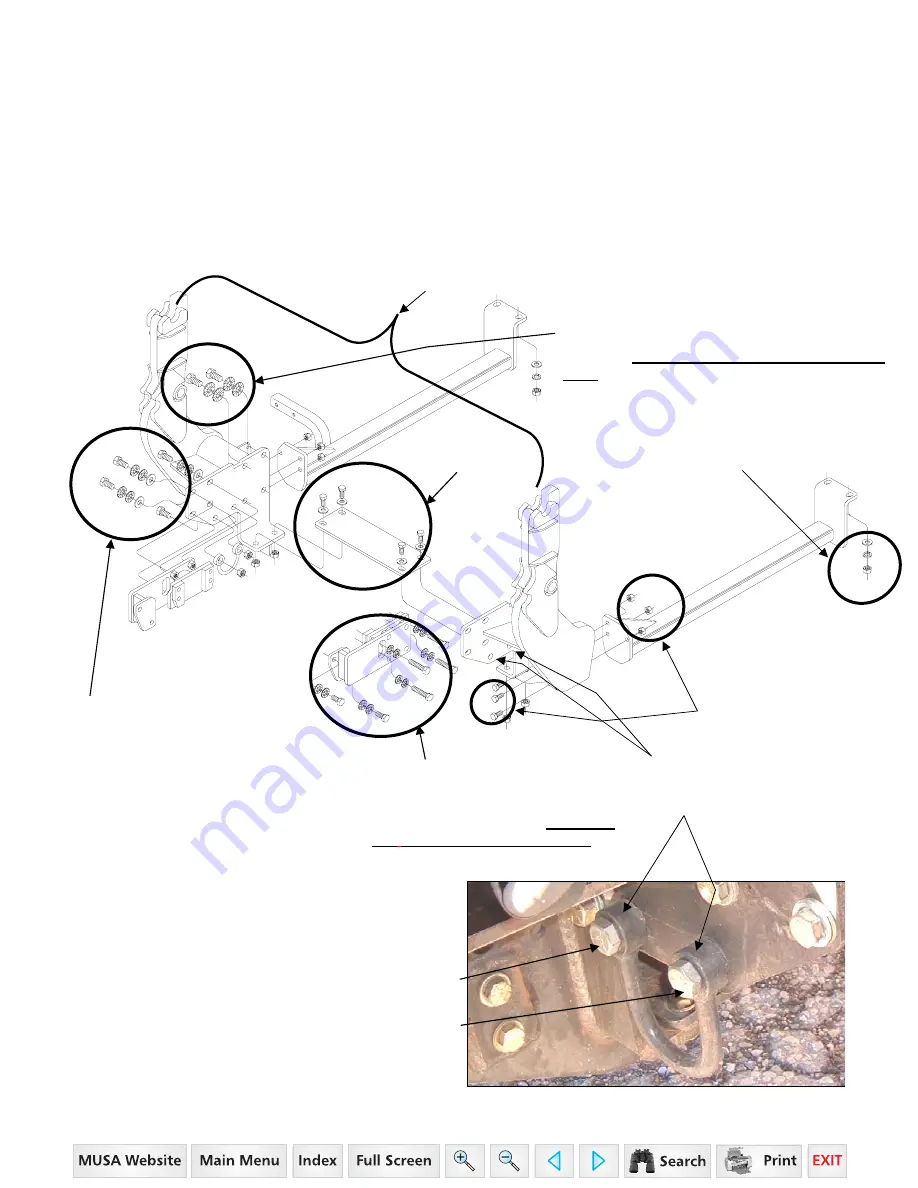

3.2.8. If equipped, install tractor tie down hook to each

loader centerbracket using hex head cap screw ¾”-10 x

2.0” Grade 8 and stover hex locknut ¾”-10, 2 places as

shown.

Hex Head Cap Screw ¾”-10 x 2.0” Grade 8, Stover

Hex Locknut ¾”-10, 2 places

Tractor Tie Down Hook

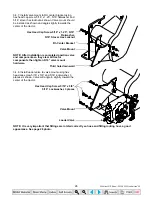

1

st

- Engine hardware

14-2 x 35mm bolts, 9/16” disc-lock

washers, 14-1.5 x 65mm bolts,

9/16” disc-lock washers Torque to

107 ft. lbs. (6 places each side)

2

nd

- Center casting hardware

¾”-10 x 1.75” Gr. 8 bolts, ¾” disc-lock

washers. Torque to 172 ft. lbs. (4 places each

side)

6th

36” Centers after installation

5th

3

rd

– Front Rail hardware

5/8”-12 x 2.0” Gr. 8 bolts, 5/8” disc-lock

washers. Refer to torque chart, page 82.

(4 places each side)

4th

Use these loader mount

plate holes to install Tractor

Tie Down Hooks.

35 Series 4WD, Model - 3535 & 4035 Loader June’08