24

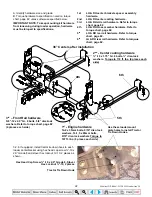

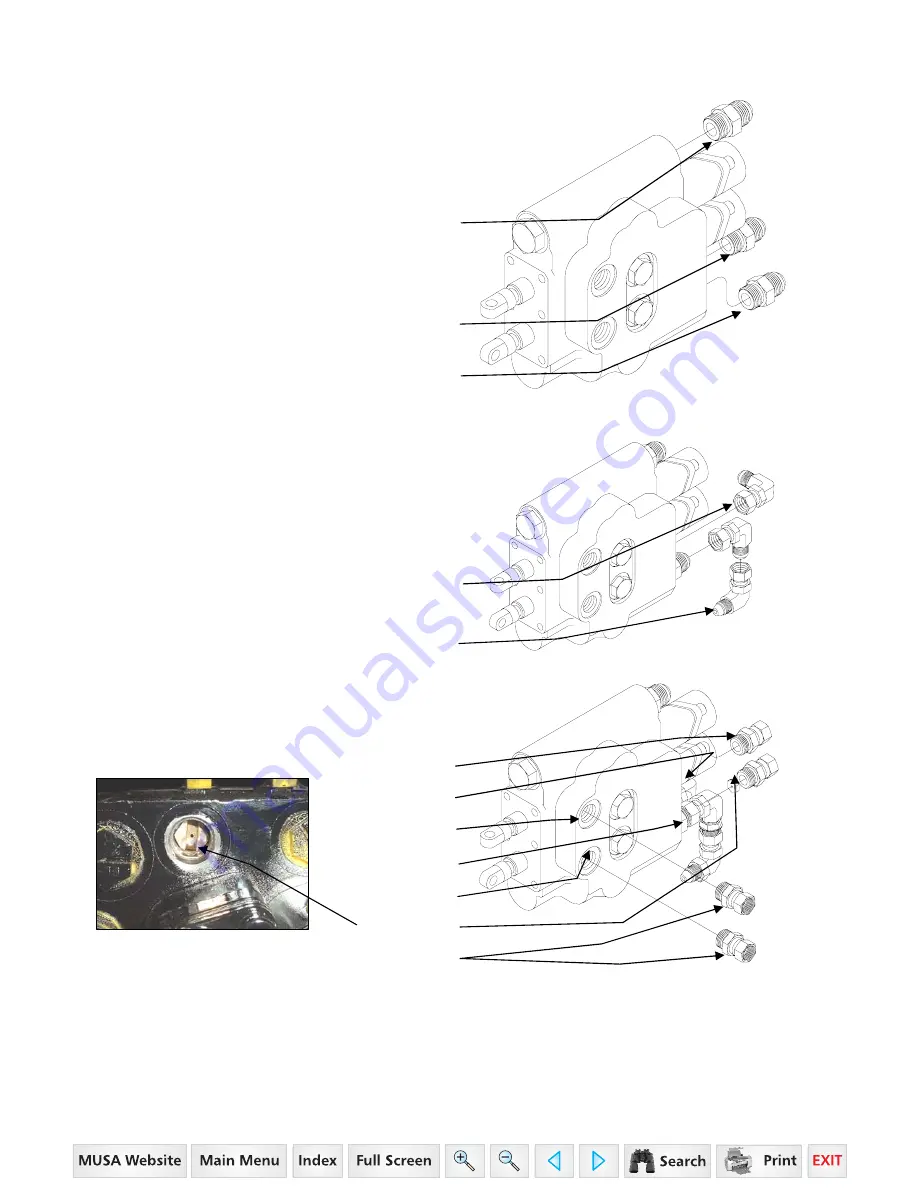

3.4. HYDRAULIC INSTALLATION

3.4.1. Install three ¾” ORBM x ¾” JICM straight fittings

into the “In”, “Out” and “PB” ports of the loader valve.

¾” ORBM x ¾” JICM straight fitting in

“In” Port of Loader Valve

¾” ORBM x ¾” JICM straight fitting in

“Out” Port of Loader Valve

¾” ORBM x ¾” JICM straight fitting in

“PB” Port of Loader Valve

3.4.2. Install ¾” JICF x ¾” JICM 90° fitting to fitting

installed in the “Out” port of the loader valve. Position

this fitting as shown. Install two ¾” JICF x ¾” JICM 90°

fittings to fitting installed in the “PB” port of the loader

valve. Position these fittings as shown.

¾” JICM x ¾” JICF 90° fitting in

“Out” Port of Loader Valve

¾” JICM x ¾” JICF 90° fittings in

“PB” Port of Loader Valve

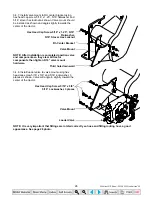

3.4.3. Install four 9/16” ORBM x 9/16” JICF straight

fittings to ports A, B, C and D. Install orifice plate in port

“D” with the slotted side facing out or away from valve

body as shown.

9/16” ORBM x 9/16” JICF straight fitting

Port “B”

Port “A”

Port “D”

Port “C”

Orifice Plate

9/16” ORBM x 9/16” JICF straight fitting

NOTE: Orifice is used to reduce bucket cylinder cavitation during regular dump operation. If your

operation requires a different orifice size, contact factory for blank orifice plate. Blank orifice can be

drilled to your loader application. Smaller hole will reduce cavitation at low RPM but it will decrease dump

speed. Larger hole will increase cavitation at low RPM but it will increase dump speed. Use of regen

during operation will eliminate any cylinder cavitation. See valve operation instructions in this manual for

further loader valve operation instructions.

35 Series 4WD, Model - 3535 & 4035 Loader June’08