35

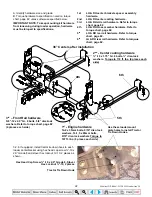

4.5. LOADER MOUNTED VALVE EQUIPPED WITH SINGLE HANDLE CONTROLLER

4.5.1. Your loader utilizes a series type loader mounted valve equipped with single handle controller and it will function as

described.

Number 1 Position:

Pull single handle controller back to raise loader.

Number 2 Position:

Push the single handle controller forward slightly to

lower loader.

Number 3 Position:

Push the single handle controller full forward to

activate float position.

Number 4 Position:

Push the single handle controller outward to dump

attachment (normal dump).

Number 5 Position:

Pull the single handle controller inward to roll back

attachment.

Number 6 Position:

Pull the single handle controller downward and

push the single handle controller outward to raise

loader and to dump attachment simultaneously.

Number 7 Position:

Push the single handle controller forward and push

the single handle controller outward to lower loader

and to dump attachment simultaneously.

Number 8 Position:

Push the single handle controller forward and pull

the single handle controller inward to lower loader

and to roll back attachment simultaneously.

Number 9 Position:

Push the single handle controller fully outward to

activate regen position on the loader valve which will

dump attachment at a faster rate.

Number 10 Position:

Pulling the single handle controller downward while

pulling the single handle controller inward is not

recommended for scooping because of insufficient

lifting force plus loader will not operate after bucket

contacts rollback stops.

NOTE: This loader valve is a series valve. If you, the operator, extend or retract bucket cylinders fully

with valve handle in a two function position (positions 6, 7, 8 or 10), loader will stop raising or lowering

when bucket cylinders reach the end of their stroke. Operator must then position single handle

controller to a one function position (positions 1, 2, 4 or 5) to allow the loader to continue to operate.

IMPORTANT: If the bucket or attachment does not operate as indicated on the directional decal, lower the

bucket to the ground, stop the engine, and relieve all hydraulic pressure. Recheck hydraulic circuit

hookup to loader valve and correct.

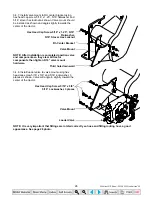

4.6. NEUTRAL POSITION

The loader external valve has a "neutral position" which prevents movement of the loader

or attachment. When the valve handle is manually released from the work position, the

valve spool will return to the neutral position. If this does not function correctly check

cable adjustment and/or check for damage to cable or single handle controller.

4.7. FLOAT POSITION

The loader valve has a "float position" incorporated into the lift cylinder circuit which allows the loader to float.

This float feature is important for satisfactory operation when scraping, sweeping, leveling, or any job where it is

necessary to follow the contour of the surface. To activate float position, lower the bucket or attachment and

push the single handle controller all the way forward into detent. The valve will stay in float detent position until

the operator manually pulls the single handle controller out of detent position to deactivate float.

Directional decal

35 Series 4WD, Model - 3535 & 4035 Loader June’08