36

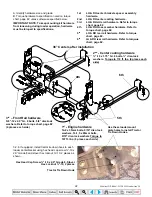

4.8. REGENERATIVE DUMPING POSITION

Your valve is equipped with a regen position in the bucket circuit. When digging with the loader, feather the single

handle controller outward to angle the bucket forward and put the weight of the tractor on the cutting edge. If you

position the loader valve into regen position, weight of the tractor may not remain on the cutting edge. The loader

valve has a “Regenerative Spool” incorporated in the bucket spool. The tilt cylinders must be connected to this

spool allowing the operator to choose normal dump or fast dump during loader operation. While using regen

position some oil will bypass over relief which could cause a small amount of hose chatter and hydraulic relief

noise which is normal to operation.

NOTE: Regen position will speed up dump operation in most applications. However, operator may not see

significant speed increase at high RPM due to some oil being forced relief. Use of regen position will

eliminate bucket cylinder cavitation.

NOTE: Use normal dump position when digging with loader. This will allow operator to put full tractor

weight on cutting edge during this operation. The regenerative function can then be used when dumping

load from bucket.

NOTE: Valve circuits must be hooked up correctly to allow regen to operate correctly.

IMPORTANT: If the bucket or attachment does not operate as indicated on the directional decal, lower the

bucket to the ground, stop the engine, and relieve all hydraulic pressure. Recheck hydraulic circuit

hookup to loader valve and correct.

NOTE: Use of regen function during dumping will eliminate attachment cylinder cavitation, which will

reduce or eliminate any free movement of bucket or attachment during loader operation.

CAUTION: Do not tamper with relief valve setting. The relief valve is pre-set at the factory.

Changing the setting can cause overloading of the loader and tractor, which may result in serious

injury.

IMPORTANT: If the bucket and lift circuits do not operate correctly check single lever controller pivot

position along with cable position.

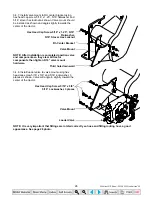

4.9. INITIAL LOADER OPERATION

NOTE: Keep engine speed at low idle during the initial loader operation.

Before operating the loader, fully raise and lower the boom two or three times. Then raise the loader bucket

approximately four (4) feet above the ground and cycle the tilt cylinders two or three times. Lower the bucket or

attachment to the ground. Check the tractor hydraulic fluid level and fill as required. Refer to the tractor Operator

Manual for the proper hydraulic fluid and the correct hydraulic fluid level.

CAUTION: Before leaving the tractor seat, lower attachment or loader boom to ground, stop

engine, lock brakes, relieve hydraulic pressure, and remove key.

IMPORTANT: Always keep the cylinders in a retracted position when the loader is not in use to guard

against rust and contamination which may cause damage to the cylinder rods and hydraulic system.

35 Series 4WD, Model - 3535 & 4035 Loader June’08