37

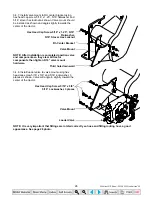

IMPORTANT: Always lock loader

valve handle in locked position when

loader is not in use or when loader

has been parked from tractor.

Push lock downward until red button

is exposed for locked position

Pull lock upward until green button

is exposed for unlocked position

NOTE: The Single Handle Controller

is equipped with a handle lock that

locks loader valve in neutral

position. This lock will not prevent

leak down of loader.

NOTE: The Single Lever Controller lock is used to prevent accidental actuation of loader valve when

loader is not in use or during transportation.

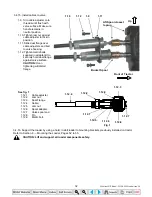

4.10. REMOVING AIR FROM HYDRAULIC SYSTEM

Repeat raising and lowering the loader boom and bucket until all the air is removed from the system and the

system responds properly.

Check the tractor hydraulic fluid level and fill, if required.

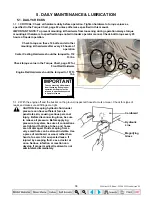

NOTE: Your loader lift and attachment circuits will have some leak down. This drift down is normal and is

caused by loader valve spool leakage. Always position loader on the ground when not in use and be alert

while transporting large loads a long distance. To check for acceptable leak down, see section 18. Leak

Down Inspection. This test must be run and leak down must be above these rates before any warranty is

applied for.

NOTE: Always change hydraulic oil in tractor as specified in tractor manual. Contaminants in hydraulic

system will cause damage to loader valve spools, increasing leakage rate which is not covered under

warranty.

NOTE: Use only recommended hydraulic oil as specified in tractor operators manual. Failure to follow

these instructions could cause damage to loader hydraulic components and can increase loader leak

down rate.

35 Series 4WD, Model - 3535 & 4035 Loader June’08