72

IMPORTANT: Always check leakage of lift cylinder seals before you test lift circuit

loader valve spool leakage.

18.2. LEAKAGE TEST FOR LIFT CYLINDER SEALS (Open Center Systems)

NOTE: Clean all parts thoroughly before disassembling any fittings. Cycle or operate the hydraulic system till

the control valve is warm to the touch.

18.2.1. Install pressure gauges in the lift cylinder rod and base end circuit.

18.2.2. With no load in bucket raise loader to full height and then hold pressure on unit for a few seconds. Read

Base end pressure it should equal tractor hydraulic system pressure. Leave unit raised for a 5 to 10 minutes and

then read rod end pressure. Rod end pressure should read zero. If pressure starts to increase in rod end and or

base end of cylinder. Lower loader and repair or replace damaged lift cylinder. If rod end pressure does not

increase no cylinder repair is required. This test can also be done with some load in bucket and with the loader

only raised slightly off of ground. This will increase the pressure in the cylinder and check the seals at a higher

pressure.

NOTE: Make sure that the pressure in the rod end circuit is zero or very low when starting this test.

OPTIONAL WAY TO CHECK LIFT CYLINDER SEAL LEAKAGE ON OPEN CENTER

SYSTEMS. (FOLLOW THESE INSTRUCTIONS IF CHECKING A CLOSED CENTER OR

LOAD SENSE SYSTEM)

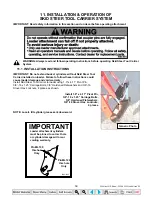

18.2.3. Remove lift cylinder rod end hose.

Install tee fitting with a high pressure ball

valve and drain hose assembled to the

rod end of the lift cylinder circuit. Insert

end of drain hose into a drain pan.

Tee Fitting

High Pressure Ball Valve

Drain Hose

Lift Cylinder Rod End Hose

Install pressure gauge in

the

base and rod end of

Lift cylinder

35 Series 4WD, Model - 3535 & 4035 Loader June’08