73

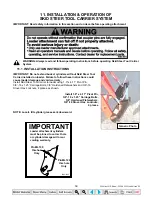

High Pressure Ball Valve and fittings

installed on a loader.

Lift Cylinder Rod End Hose

Tee Fitting

High Pressure Ball Valve

Drain Hose

18.2.4. Install a pressure gauge in the lift circuit base end.

18.2.5. With high pressure ball valve in off position, place a load in the bucket and raise loader to some height.

The load in the bucket and the lift height should be such that it induces a target reference pressure of 1500 psi in

the cylinders.

18.2.6. Disconnect rod end lift cylinder circuit from loader valve by disconnecting quick coupler. If quick coupler

does not exist install one in line before proceeding with this test.

18.2.7.

Slowly

open high pressure ball

valve directing drain hose to drain pan.

Note: If oil flows out of drain hose and

loader lowers, cylinders will need to be

repaired or replaced.

Note: If no flow is seen, no repair of lift

cylinder is required.

18.2.8. Reconnect rod end of lift cylinder

circuit by reconnecting quick coupler.

18.2.9. Lower loader to ground. Relieve

pressure and remove high pressure ball

valve and tee fitting. Re-connect loader

hose and fitting.

Base end

Of lift

cylinder.

Rod end

of lift

cylinder.

35 Series 4WD, Model - 3535 & 4035 Loader June’08