© MAHLE

16 | ACX11 80 | Com m issioning

en

4.3 ACX11 80

m

The ACX1180 is designed for 120 VAC ± 10 %, 50/60

Hz. Follow the information on ACX1180 rating plate.

1. Set the ACX1180 on a flat, vibration-proof surface.

2. Actuate the caster brake to stop ACX1180 from rolling.

3. Connect the power supply cable to the power supply.

4. Switch on the main switch.

@ The unit will prompt user to Select Language.

@ The fan is switched on.

t

The fan runs while the ACX1180 is switched on.

WE I G H T =

# #. #

L B

A U T O M A T I C

S T A R T ?

4.3.1 Set t ing

language

1. During first time setup, the unit will automatically prompt

user to select a language. After this, it will be necessary

to use

or

to get to Set up and press YES.

1. Press YES again to enter Selec t able Opt ions (or press

and hold #4 key from main menu).

2. Select language with

.

3. Store selection with YES.

4.3.2

Set t ing dat e and t im e

1. From main screen, use or to get to Set up and

press YES.

2. Use

or

to scroll to Maint enanc e Opt ions and

press YES again.

3. Press NO until Set Dat e and Tim e is displayed.

4. Alter values with

or

.

5. Move to next value with

.

6. Store entries and return with YES.

4.3.3

Act ivat ing / deac t ivat ing pr int er, buzzer

1. From main screen, use or to get to Set up and

press YES.

2. Press YES again to enter Selec t able Opt ions

3. Press YES button to scroll though various options.

4. Activate/deactivate by using or to select YES or

NO.

5. Store entries by changing selection and pressing the

YES button. Escape by pressing NO button.

4 .4 Set up

4 .4.1 Select able

Opt ions

1. From main screen, use or to get to Set up and

press YES.

2. Press YES again to enter Selec t able Opt ions.

3. Press YES button to scroll though various options.

4. Activate/deactivate by using or to select YES or

NO.

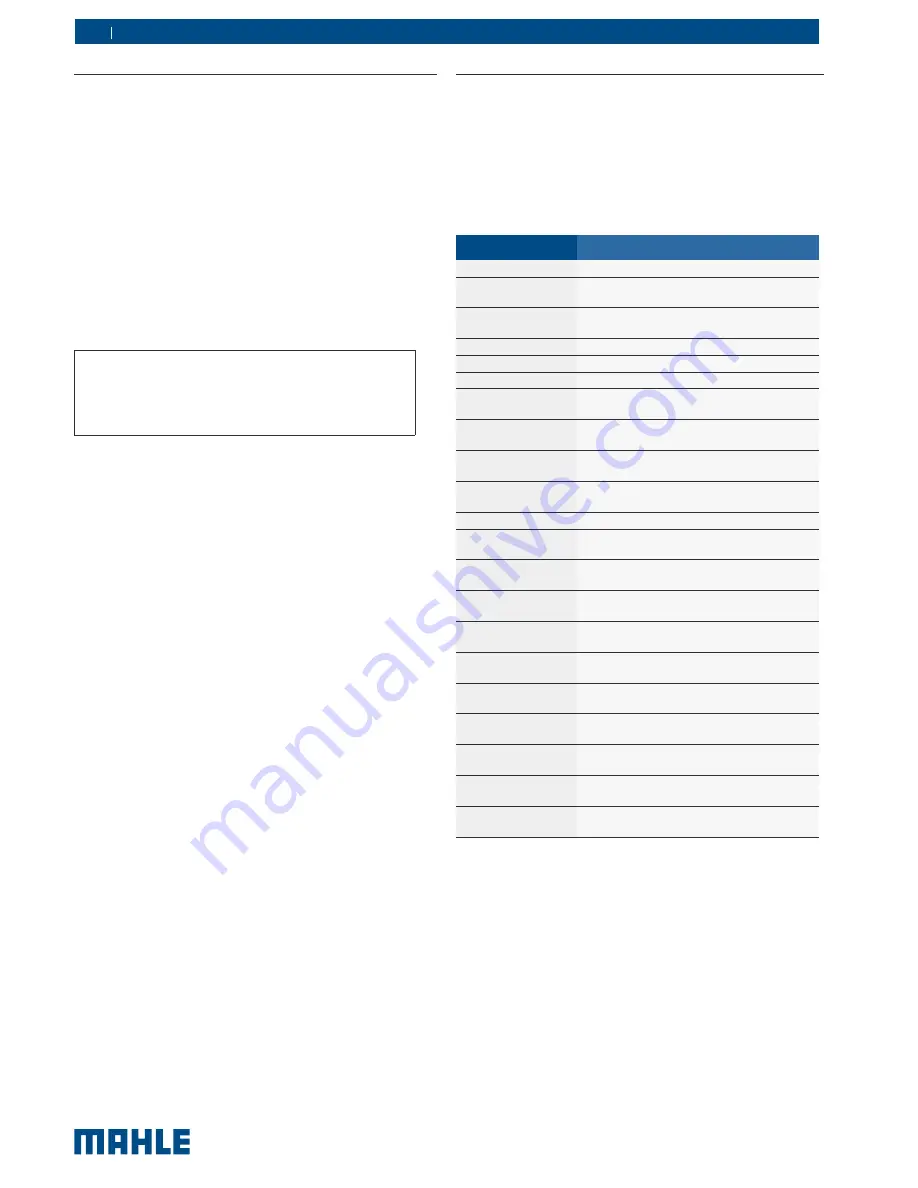

Opt ion

Descr ipt ion

Select language

Select language to be displayed on screen.

Buzzer enabled?

Audible alarm additionally sounds in the

event of error messages.

Refrig ID installed?

Optional accessory that can be purchased

and added at user convenience.

AC Cap DB installed? Optional accessory that can be enabled.

Printer installed?

Optional accessory item.

Print to flash drive?

Print results to flash drive for records.

Low voltage detect

enabled?

Only applicable to "C" version units.

Micron vacuum sen-

sor enabled?

Only applicable to "C" version units.

Password protection

enabled?

Optional setting if password protection pre-

ferred.

VIN entry enabled?

Allows technician to enter vehicles VIN

number that is being serviced.

Operator ID entry

Only applicable to "C" version units.

AC test mode ena-

bled?

Only applicable to "C" version units.

Vacuum pump oil life

test enabled?

Only applicable to "C" version units.

Refrigerant liquid

flush enabled?

Only applicable to "C" version units.

Techalert demomode

enabled?

If TechALERT is puchased, the demo can be

enabled to demonstrate use.

High pressure leak

detect enabled?

Only applicable to "C" version units.

Automatic weighing

oil injection enabled?

Only applicable to "C" version units.

Automatic weighing

oil drain enabled?

Only applicable to "C" version units.

High voltage oil flush

enabled?

Only applicable to "C" version units.

Fill cylinder enabled? Allows user to fill internal cylinder from exter-

nal refrigerant tank.

Manual oil injection

enabled?

Allows user to manually inject oil between

vacuum and charge procedure.