EN | 26 | ACX150/250 | Non-permanent junction

© MAHLE

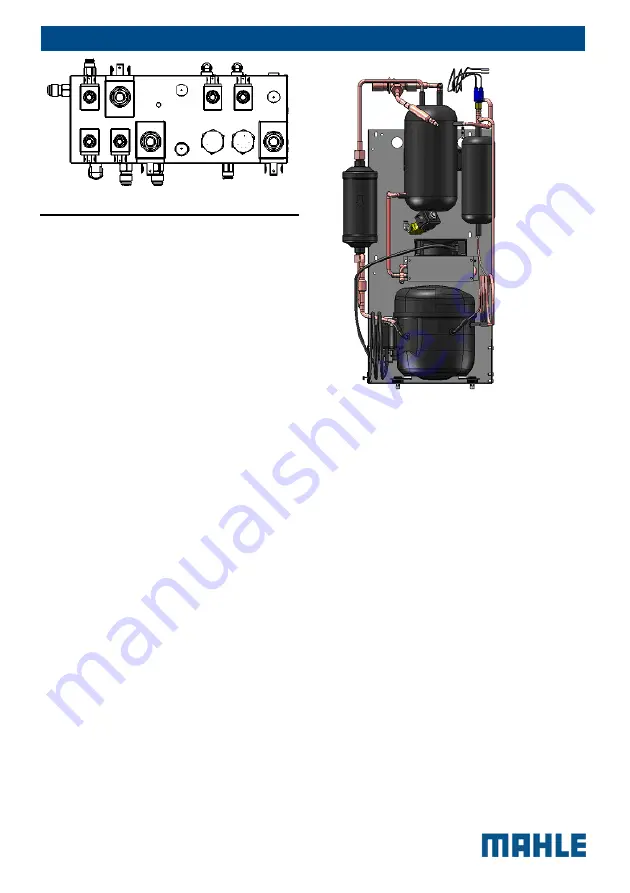

10.5

Suction unit chart

The suction unit is a group made up of

various pressurised equipments

interconnected through brazed piping,

which according to the PED directive fall

under article 3 paragraph 3.

A routine maintenance operation is the

replacement of the dryer filter, the

procedure of which is outlined in the user

manual.

Safety against the risk due to pressure of

the refrigerant fluid inside the suction unit

is ensured by a safety gauge installed

during manufacturing.

In case of replacement of the pressure

switch or the unit, use of new and original

spare parts not contaminated by other

substances is recommended as well as

requesting the declaration of conformity

proving the effective

test of the

components in the beginning.

The assistance centre is responsible for

workmanlike assembly and for checking

before new commissioning according to

the prescriptions provided for by the

regulations in force in the country of use;

in particular, the assistance centre will

have to guarantee that the assembly

ensures a perfect tightness and that the

safety components are installed

appropriately so as to ensure operation is

not jeopardized.

SUCTION UNIT Art. 3.3 (Dir. 97/23/EC)

11

Non-permanent

junction

Here below some instructions on the use

of Loctite® 577 on the thread of some

non-permanent junctions in the

pneumatic circuit of the ACX stations.

The product polymerizes when air is

absent and when in contact with

metal

;

its aim is preventing slackening caused

by impacts and vibrations. Yet, after

application and fixing onto the

junction/thread, you must tighten and

then wait several hours, in relation to the

type of coupling between metals, before

the product can get its maximum

performance in terms of hold/resistance.

For one’s own and other people’s safety,

the operator/user of the Loctite® 577

product must consider that it must be

employed in well-ventilated premises and

that protecting eyes and hands with

L T

V A I

R

HP SENSOR

LP SENSOR

TP SENSOR

CHECK VALVES

Summary of Contents for ACX150

Page 1: ...MAHLE ACX150 250 SERVICE MANUAL fflRHLE...

Page 3: ...EN 2 ACX150 250 Contents MAHLE 16 Diagnostic 30 16 1 Failure list 30...

Page 32: ...EN 31 ACX150 250 Diagnostic MAHLE ATTACHMENT 1 REFRIGERANT FLUID CIRCUIT ACX150 250...

Page 35: ...EN 34 ACX150 250 Diagnostic MAHLE Vacuum ACX150 250...

Page 36: ...EN 35 ACX150 250 Diagnostic MAHLE Oil injection ACX150 250...

Page 37: ...EN 36 ACX150 250 Diagnostic MAHLE Refrigerant recharge ACX150 250...

Page 83: ...DE 35 ACX150 250 Diagnose MAHLE ANHANG 1 REGELKREIS K LTEMITTEL ACX150 250...

Page 86: ...DE 38 ACX150 250 Diagnose MAHLE Vakuum ACX150 250...

Page 87: ...DE 39 ACX150 250 Diagnose MAHLE leinspritzung ACX150 250...

Page 88: ...DE 40 ACX150 250 Diagnose MAHLE Entladung K hlmittel ACX150 250...

Page 134: ...FR 34 ACX150 250 Diagnostic MAHLE ANNEXE 1 CIRCUIT DU LIQUIDE REFRIGERANT ACX150 250...

Page 137: ...FR 37 ACX150 250 Diagnostic MAHLE Vide ACX150 250...

Page 138: ...FR 38 ACX150 250 Diagnostic MAHLE Injection d huile ACX150 250...

Page 139: ...FR 39 ACX150 250 Diagnostic MAHLE R frig rant de recharge ACX150 250...

Page 150: ...FR 50 ACX150 250 Diagnostic MAHLE R FRIG RANT N EST PAS SUPPORT l analyseur...

Page 152: ...FR 52 ACX150 250 Diagnostic MAHLE...

Page 185: ...IT 33 ACX150 250 Diagnosi MAHLE ALLEGATO 1 CIRCUITO FLUIDO REFRIGERANTE ACX150 250...

Page 188: ...IT 36 ACX150 250 Diagnosi MAHLE Vuoto ACX150 250...

Page 189: ...IT 37 ACX150 250 Diagnosi MAHLE Iniezione olio ACX150 250...

Page 190: ...IT 38 ACX150 250 Diagnosi MAHLE Ricarica refrigerante ACX150 250...