I N D U S T R I E M Ü H L E N | I N D U S T R I A L G R I N D E R

9.2 Cleaning the grinding mechanism

1. Pull out the power supply plug !

2. Rotate the rotary knob (11) to „coarse“.

3. Unscrew the two screws (13) on the grinder casing cover (12) and

then remove this cover.

4. Take the carrier (10) out of the slot of the pre-breaker.

5. Pull the pre-crusher (9) off the motor shaft. Use a puller.

6. Clean the grinding mechanism with a fi ne brush and remove any

foreign objects.

7. Before pushing the pre-crusher (9) back onto the shaft again, lubri-

cate the shaft with non-corrosive, resin-free and foodstuff-compat-

ible grease (e.g. Vaseline).

8. After you have pushed the pre-crusher onto the shaft, line up the

two slots so that you can then easily re-insert the previously re-

moved driver (10).

The rounded side of the driver must point toward the

motor.

9. Clean the contact surfaces of the grinder casing and grinder casing

cover (12) carefully in order to remove any form of soiling.

During re-assembly, no ground material is allowed to

be sticking to the surfaces where the grinder casing

and the grinder casing cover lie on top of one another.

10. Screw the grinder casing cover (12) down tightly with the two

screws while changing the side (13) several times.

11. Rotate the rotary knob to the desired grind degree. The grinder is

now ready for operation again.

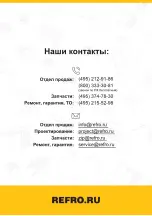

11

9

10

11

12

13

Summary of Contents for DK15 Series

Page 1: ......

Page 16: ...I N D U ST R I E M H L E N I N D U ST R I A L G R I N D E R...

Page 18: ......