uk

│ 9. Installation ‒ Electrical connection

18

4. Fix the fan into position at the installation

location using fixing material that is

approved for the corresponding load.

Use spring washers or lock nuts to

ensure long-term fixing. Take note of

the torque values quoted by the dowel

manufacturer. Build in the steel wall

ring without distorting it by twisting or

squeezing it. The impeller must not rub.

5. Check both the free running of the impeller

and the air gap between the impeller and

the steel wall ring, by turning the impeller

by hand.

The impeller must not rub and the air

gap must be more or less the same

all the way round.

6. Install a shutter or a protective grille on the

outside, in order to safeguard the fan

against foreign bodies falling into the air

channel. Insure there is protection against

accidental contact, in accordance with EN

ISO 13857.

Always use new lock nuts in

accordance with EN ISO 7041, when

assembling and dismantling.

9.2 Electrical connection

DANGER

Danger to life from electric

shock.

Prior to accessing the connection

terminals, switch off all supply

circuits. Switch off mains fuse,

secure against being accidentally

switched back on and position a

visible warning sign.

NOTICE

Risk of damage to unit in the

event of short-circuits.

Insulate any unnecessary cable

cores.

Information

● Always note the relevant specifications for

electrical installations and when fitting

equipment. In Germany observe DIN VDE

0100 and the corresponding parts in

particular.

● Connect the fan to a current-dependent

protection device. This should be supplied

by the customer

see protection device

operating instructions for relevant data.

Procedure

1. Switch off mains fuse and prevent from

being started up again. Fit warning sign.

2. Remove the terminal box cover [3].

NOTICE

Danger of short circuits and

damage to unit. Water may

penetrate the terminal box if

the power cable is introduced

incorrectly or if sealing

elements such as a self-

sealing grommet, cable

grommet or cable screw-

connections are not fitted

correctly.

Install the sealing elements

such that the power cable is

held snugly in place.

3. Install suitable sealing element such as a

self-sealing grommet, cable grommet or

cable screw-connections.

4. Guide the power cable into the terminal

box such that the sealing element fits

around the cable sheathing completely.

If necessary, seal the terminal box on-site.

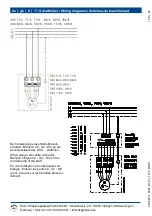

5. Wire fan to the terminal block according to

the wiring diagram (

Chapter 17). Note

tightening torque of screws of 0.7 Nm.

NOTICE

Risk of damage to unit if

unauthorised external control

device is used.

Only connect control devices

with a current-dependent

protection device.

6. Wire external control device to the terminal

block according to the wiring diagram

(

Chapter 17). Note tightening torque

of screws of 0.7 Nm.