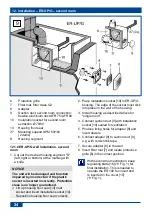

12. Installation ‒ ER-UP/G

21

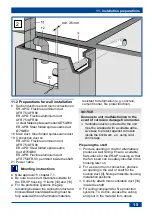

12. Housing installation

●

ER-UP/G housing

●

ER-UPD housing

●

ER-UPB housing

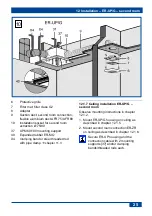

12.1 Installing ER-UP/G housing

12.1.1 Impermissible connections on

ER-UP/G housing

The following are not permitted:

●

Second room connection with an ER 60

fan insert (all models).

●

Second room connection in combination

with Centro exhaust air elements.

●

Connecting a WC odour extraction unit in

combination with Centro exhaust

elements.

●

Use of an ER fan or Centro exhaust air

element in the bathroom or toilet room if

other rooms in the apartment are to be

vented with the same unit at the same

time.

12.1.2 Mounting instructions for ER-UP/G

housing (

chapter 11.1 and approval)

ER-UP/G are equipped with a plastic housing

without fire protection equipment. The ER-

UP/G housing may be installed in the

following installation positions:

●

Mounting on wall: With upward, right-hand

or left-hand air outlet direction (exhaust

socket). Installation with mounting support.

●

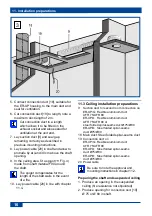

Mounting on ceiling and suspended

ceiling: Installation with mounting support.

●

Mounting on ceiling and non-suspended

ceiling: Mounting directly on the ceiling.

Suitable mounting material is to be supplied

by the customer.

The plastic shutter should be prepared

according to chapter 11.5.1 so that it

closes fully sealed in the installation

position.

The ER-UP/G housing

must be inserted

without any

distortion.

Failure to do so will

mean that the fan insert cannot engage

correctly in the ER-UP/G housing and the

degree of protection stated on the rating

plate is no longer ensured.

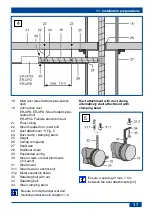

Break open one of the housing segments [S]

to use the second room connection set

ER-ZR or the extraction socket ER-AS.

A WC seat ventilation unit is connected to the

ER-UP/G housing using the Ø 70 extraction

socket ER-AS.

The WC seat ventilation unit must

not be connected to the second room

connection socket or the Centro

exhaust air element.

Use expanded rubber ER-MO for acoustic

insulation of thin ceilings capable of reso-

nance (

accessories).

12.1.3 Important information about

plastering

●

Max. compensable plaster overshoot

7 mm.

●

Max. protruding housing edge 20 mm, can

be compensated for with spacing frame

DR 60/100.

●

Installation at a depth of 50 to 100 mm can

be compensated for with the two-part wall

frame ER-MR.

●

The gap remaining between the ER-UP/G

housing and shaft must be fully sealed

with non-flammable materials resistant to

deformation so that incorrect air is not

drawn in.

●

Joints between the UPB housing and wall

can be covered with cover frame ER-AR.

We recommend keeping these

mounting and operating instructions

until final installation in the ER-UP/G

housing.

Summary of Contents for ER-UP/G

Page 3: ...1...