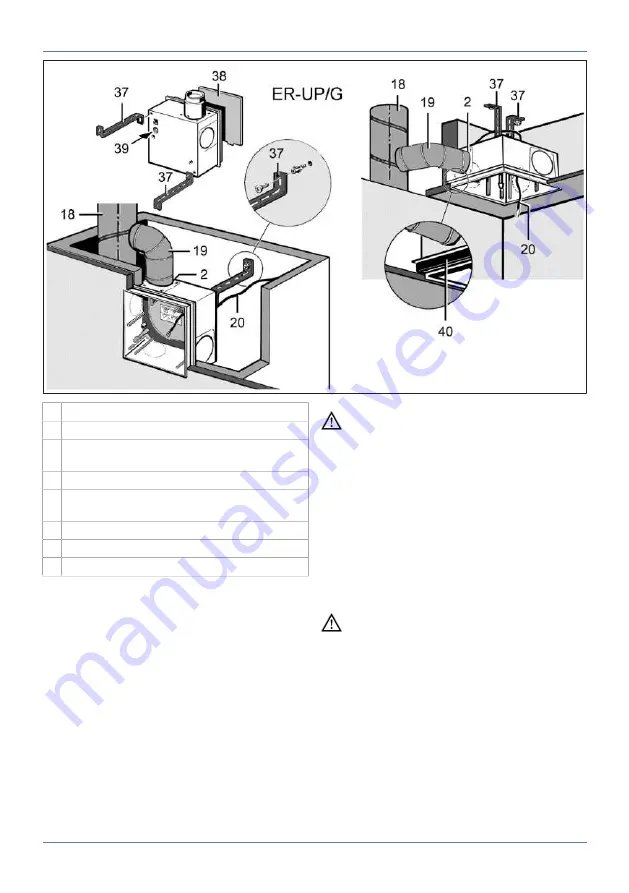

7 Housing installation

19

2 Exhaust socket with plastic shutter

18 Main duct, steel folded spiral-seams duct

19 Connection duct, AFR 80 DN 75/80 flexible

aluminium duct

20 Power cable

37 Mounting support UPM 60/100 or ER-UPM (2

items)

38 Plaster protective cover

39 Cable grommet

40 ER-MO expanded rubber

1. Remove the plaster protective cover from the

housing.

NOTICE The unit will be damaged and func-

tion impaired if the fixing screws used are in-

correctly / too long.

Fixing screws may not penetrate into the hous-

ing.

Use screws provided (mounting support

UPM 60/100).

2. Cut the mounting support to the required

length, bend it into shape and fix it to the

housing with the supplied fixing screws.

3. Mark fixing holes for mounting support on rear

shaft wall, produce holes and insert dowels.

Suitable mounting material is to be provided

by the customer.

DANGER Danger of short-circuits and

damage to the unit.

If the cable grommet is not installed correctly, wa-

ter may penetrate the housing. The degree of

protection can no longer be guaranteed.

Drive through cable grommet so that it can seal

the cable sheathing all the way round (circular,

no slots).

4. Guide power cable from rear of housing

through cable grommet into housing.

5. Insert the housing with the mounting support

into the shaft and fix it to the rear wall of the

shaft.

DANGER Fire may spread if connection

duct is incorrectly installed.

Only use permitted duct material (

).

Correctly attach connection duct to exhaust

socket.

6. Connect connection duct to exhaust socket

sealed for ventilation, e.g. with cold-shrink

tape.

7. Provide unit with electrical connection: Elec-

trically connecting the unit.

8. Insert the plaster protective cover in the hous-

ing.