8 Electrical connection

28

5.1

Steel connection socket DN 75/80 for

second room extraction on ER-UPB

6

Protective grille

7

Filter mat filter class G2

8

Adapter

9

9 Suction duct, second room connection:

Steel folded spiral-seams duct DN 75/80

1. Install housing as described in these instruc-

tions.

2. Secure suction duct and steel socket with 3

steel blind rivets or steel screws and connect

sealed for ventilation.

3. Produce fixing holes for adapter and insert

dowels.

4. Connect adapter fully sealed to suction duct,

e.g. with cold-shrink tape.

5. Secure adapter to the wall with screws.

6. Insert filter mat and fit protective grille in the

correct position.

With second room extraction, keep regulat-

ing plate somewhere safe for the final installa-

tion. This is needed to operate the ER 100 fan

insert and is inserted in the cover.

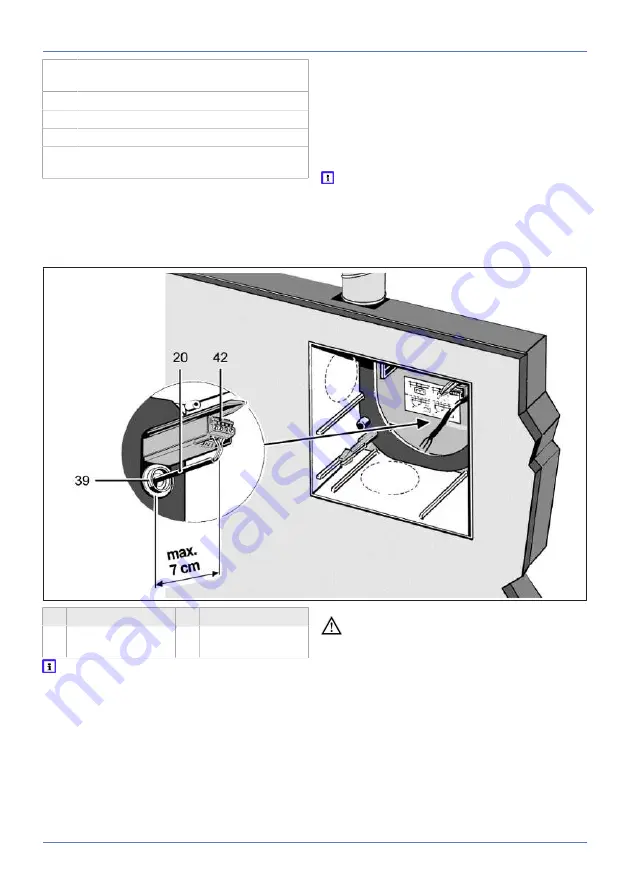

8 Electrical connection

20 Power cable

39 Cable grommet

42 Connection ter-

minal

To prevent the unit and/or electric compon-

ents from malfunctioning as a result of reverse

polarity voltages and induction (incorrect igni-

tion or glowing/flaring of LED, energy-saving

or neon lamps), the unit and electric compon-

ents connected in parallel, such as room light-

ing, should be connected via a double-pole

switch.

DANGER Danger to life from electric

shock.

Prior to accessing the connection terminals,

switch off all supply circuits. Switch off mains

fuse, secure against being accidentally switched

back on and position a visible warning sign.