7. Product information

10

7.2 Permitted exhaust air systems

In accordance with DIN 18017-3, the

following exhaust air systems are permitted

for ER-UP-GH.

Exhaust air system

ER-UP/GH

housing

aeroduct fire

protection system

no

PAM-GLOBAL RML

cast ventilation

system

no

Ceiling penetration

seal system

Yes

*

System with fireproof

shaft

no

Air extraction system

without fire protection

Yes

*

*

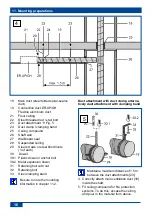

ER-UP/GH can be used inside and outside

the shaft, connection duct made from

flexible aluminium duct, second room

connection made from

flexible aluminium

duct.

7.3 Possible combinations

The ER recess-mounted exhaust air systems

described here comprise a UP housing and a

fan insert with cover.

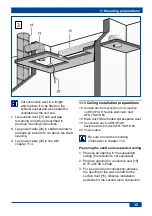

In the

shell phase

the

ER-UP/GH housing

is installed, wired and provided with a plaster

protective cover.

If the second room connection kit ER-ZR is

used, the ER-UP/GH housings can also be

used for second room extraction.

WC seat ventilation at the same time as room

ventilation is possible using the second room

connection of the ER-UP/GH housings. The

Maico extraction socket ER-AS (Ø 70) should

be used for this purpose and a connection

established to the WC seat.

Final assembly

is undertaken once the

plastering and paint work is complete.

For decentralised ventilation

, an ER 60 E

or ER 100 E fan insert is placed in the UP/GH

housing, the exhaust air filter and cover are

fitted.

ER 100 E units

are permitted for

second

room air extraction

. These can be combined

with the standard, EVZ or EG control models

chapter 12.1.1.

ER 60 units

are

not

permitted

for

the

second room connection

.

7.3.1 Recess-mounted housing ER-UP/GH

● Plastic housing without fire protection

equipment. Can be combined with ceiling

penetration seal.

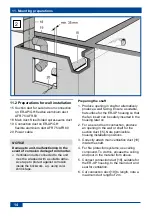

● Suited to wall or ceiling installation, inside

or outside the exhaust air shaft.

● Permissible air outlet direction with wall

installation: upwards, to right or to left.

● Plastic exhaust socket with airstream-ope-

rated plastic shutter, maintenance-free.

● For connecting second room ventilation

with knockout points at bottom, on right

and left.

7.3.2 ER 60 E or ER 100 E fan insert

● Fan insert with cover and exhaust air filter

for installation in ER-UP/GH housing.

● Electrical plug connection for quick

installation in the ER-UP housing.

● Fan insert has snap-on attachment for

easy installation.

● Cover with exhaust air filter. Trouble-free

filter change without using tools.

● It is possible to rotate the cover by ± 5° to

compensate for housings which have been

fitted at an angle.

● Filter change without tools.

● For single room or second room air

extraction with one single fan.

Exception: H models are only permitted for

single room air extraction.

● H model: Barrier-free products, as the fan

switches itself on and off automatically.

Summary of Contents for ER-UP/GH

Page 2: ...2 1...