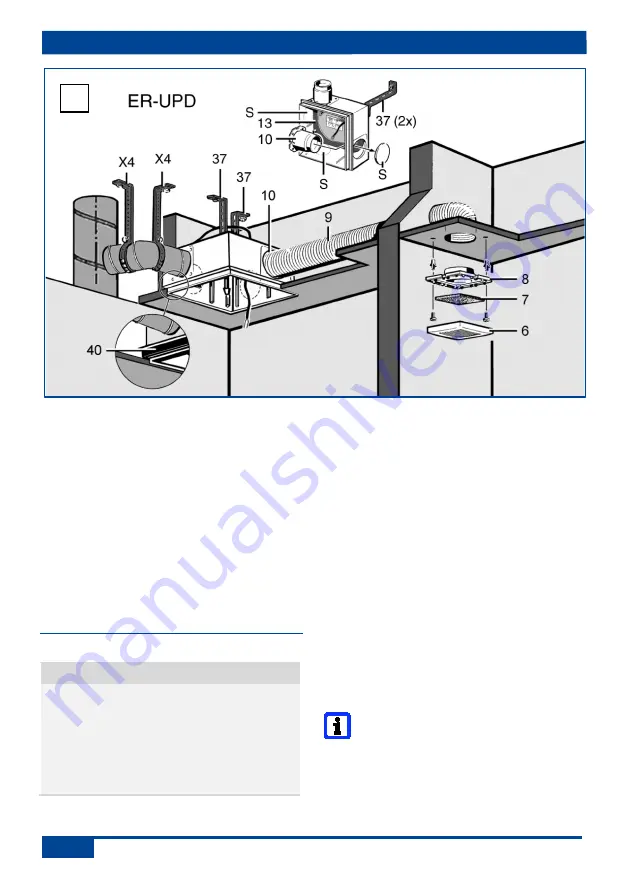

12. Installation ‒ ER-UPD - second room

28

6 Protective grille

7 Filter mat, filter class G2

8 Adapter

9 Suction duct, second room connection:

flexible aluminium duct AFR 75/AFR 80

10 Plastic installation socket for second

room extraction Ø 75/80

13 Housing floor seal

37 Mounting support UPM 60/100 (2 items)

40 Expanded rubber ER-MO

S Housing segment

X4 Clamping band or steel threaded rod

with pipe clamp

chapter 11.3

12.2.5 ER-UPD installation, second room

NOTICE

The unit will be damaged and function

impaired by incorrect air if the plastic

socket is inserted incorrectly. Protection

class is no longer guaranteed.

Lift up housing floor seal [13] near

socket and insert installation socket [10].

Reposition housing floor seal correctly.

1. Cut out the desired housing segment "S"

(left, right or bottom) at the marking with

a knife.

2. Place plastic installation socket [10] in

ER-UP/G housing. The edge of the socket

must click into place on the wall of the

housing.

3. Install ER-UPD housing as described in

chapter 12.2.4.

4. Connect suction duct [9] with plastic instal-

lation socket [10] sealed for ventilation.

5. Produce fixing holes for adapter [8] and

insert dowels.

6. Connect adapter [8] to suction duct [9],

e.g. with cold-shrink tape.

7. Secure adapter [8] to the wall/ceiling with

screws.

8. Insert filter mat [7] and locate protective

grille [6] in the correct position.

With second room extraction, keep

regulating plate [16] (

Fig. 1) for

final installation. This is needed to

operate the ER 100 fan insert and

is inserted in the cover [15] (

Fig. 1).

12