20

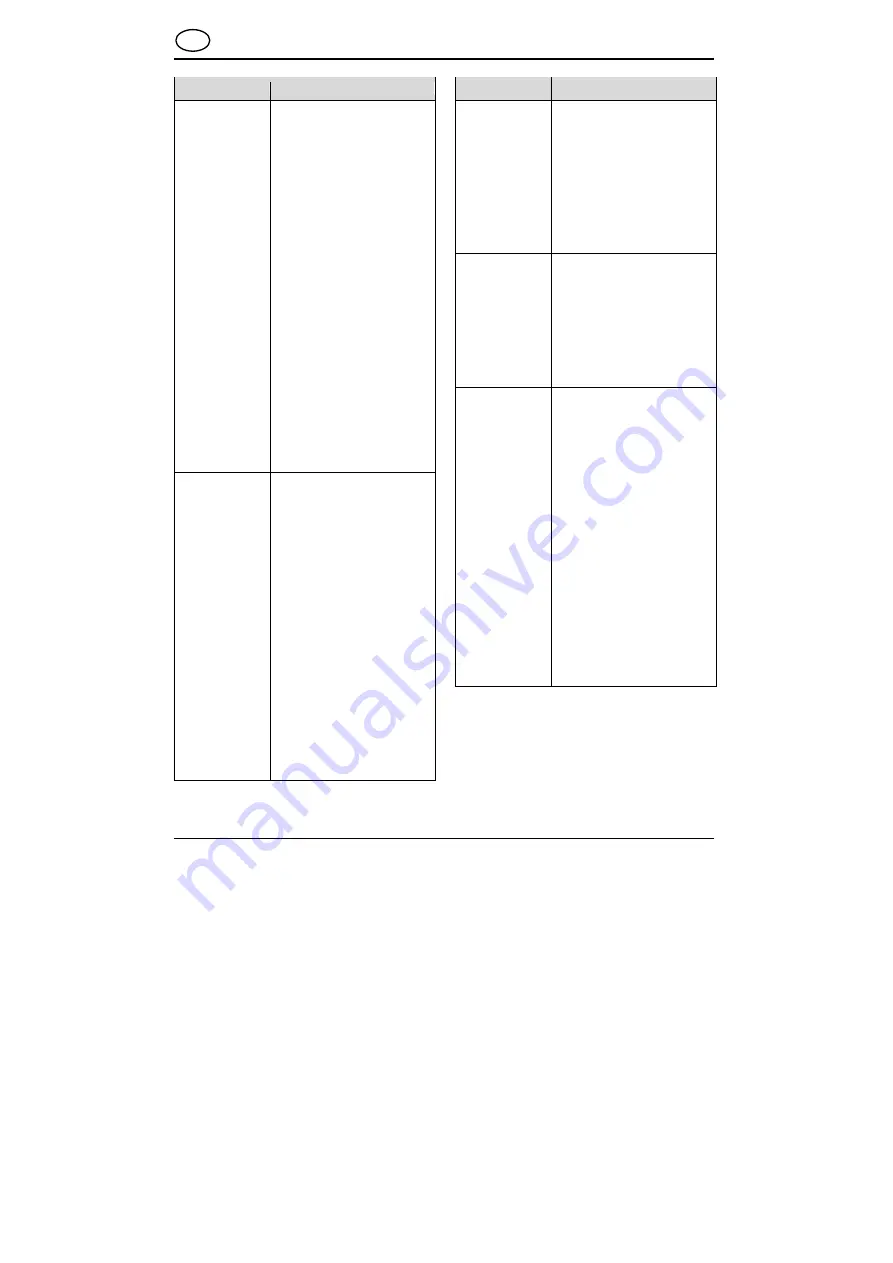

Alarm message Countermeasure

Pa INIT

ALARM

Volumetric flow

is too high.

Alarm display

[15] = On.

Relay R1 in

alarm state

(Relay

LED = On)

The required volumetric flow

cannot be achieved as the

value is outside the working

scope of the fan.

Modify the volumetric flow.

Check the ventilation

system.

Modify the layout of the

ventilation system.

Reference pressure cannot

be determined. Motor

switches to soft stop mode.

To restart, press and hold

the REST button [17] until

the alarm display goes out.

The control unit now works

as per its settings, but

without pressure alarm.

If a pressure alarm should

be set up, troubleshoot the

cause of the fault and

eliminate it, e.g. system

pressure or volumetric flow

too high. Then set the

parameter.

Pa INIT

ALARM

Pressure is

not stable.

Alarm display

[15] = On.

Relay R1 in

alarm state

(Relay

LED = On)

Pressure is too unstable.

Modify the volumetric flow.

Check the ventilation

system.

Modify the layout of the

ventilation system.

Reference pressure cannot

be determined. Motor

switches to soft stop mode.

To restart, press and hold

the REST button [17] until

the alarm display goes out.

The control unit now works

as per its settings, but without

pressure alarm.

If a pressure alarm should be

set up, troubleshoot the cause

of the fault and eliminate it,

e.g. system pressure or

volumetric flow too high. Then

set the parameter.

Alarm message Countermeasure

CA ALARM

The volumetric

flow is too low.

The required volumetric

flow cannot be reached or

held constant, as the

counter pressure gene-

rated by the fan is too high.

Modify the volumetric flow.

Check the ventilation

system.

Modify the layout of the

ventilation system.

CA ALARM

Volumetric

flow is too

high.

The required volumetric flow

cannot be held constant as

the value is outside the

working scope of the fan.

Modify the volumetric flow.

Check the ventilation

system.

Modify the layout of the

ventilation system.

CP ALARM

Pressure is

too high

Minimum volumetric flow

reached. The measured

pressure is still higher than

the required pressure.

Modify the volumetric flow.

Check the ventilation

system.

Modify the layout of the

ventilation system.

Check whether the

pressure lines [6] and [14]

are dirty.

Clean any line that is dirty

and replace them with

standard hoses of the

same quality and with the

same internal diameter if

necessary.

Make sure the pressure

line is correctly fitted at

the connection piece.

GB