Fig. J

page 30

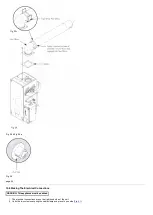

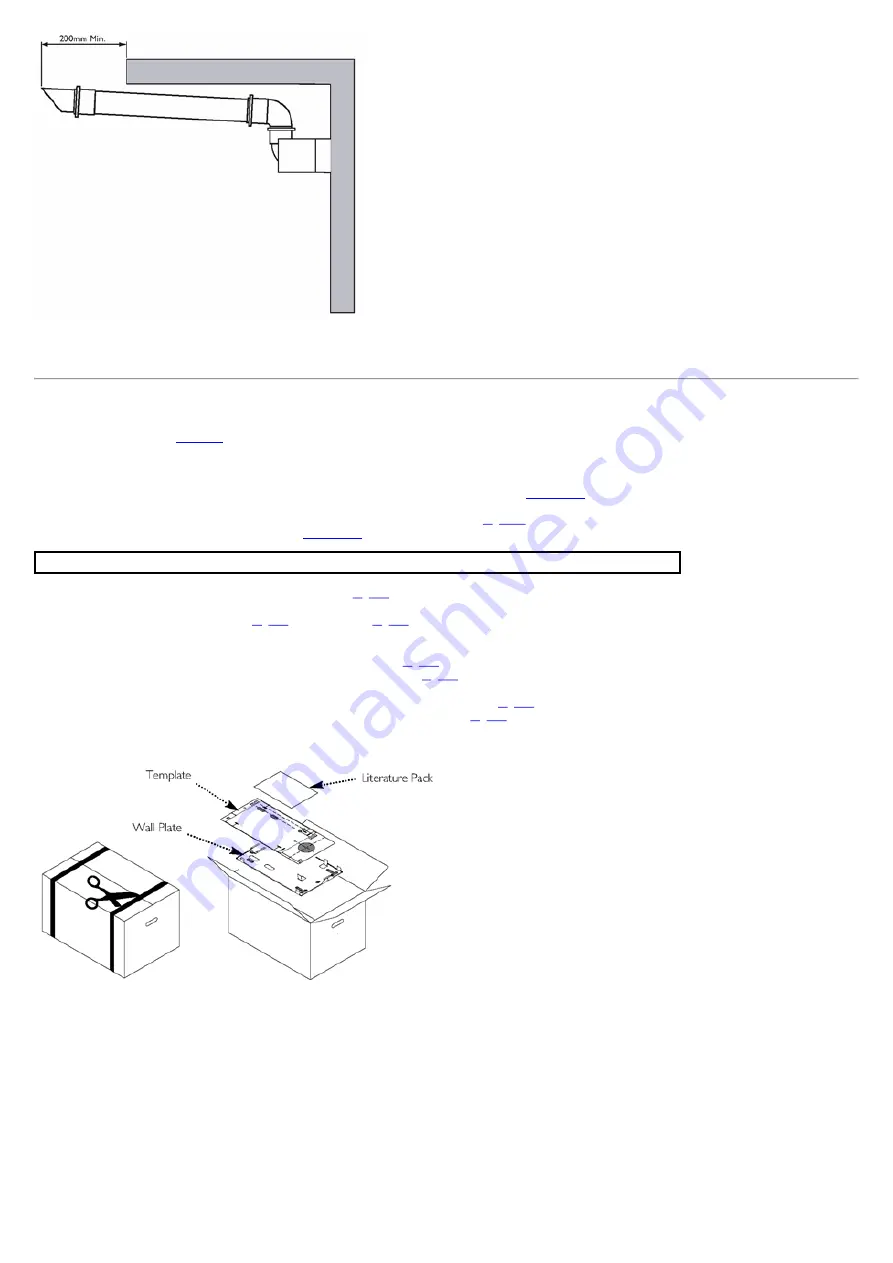

10.0 Installation

Check Site Requirements (

) before commencing.

10.1 Initial Preparation

The gas supply, gas type and pressure must be checked for suitability before connection (see

).

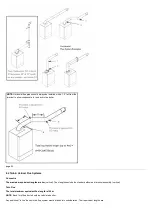

1. Cut the banding and remove the fixing template, wall plate and literature pack (

) from the carton.

2. After considering the site requirements (see

) position the template on the wall ensuring it is level both horizontally and vertically.

NOTE: When fitting Plume Displacement Kit refer to the instructions supplied for details of installation of the flue.

3. Mark the position of the fixing holes for the wall plate (

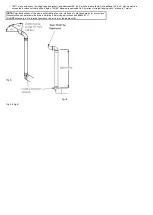

4. Mark the centre of the flue hole (rear exit). For side exit: project the horizontal side flue centre line into the corner of the room and along the wall to

where the flue hole will be drilled. (

). The diagram (

) shows the dimensions required to ensure any horizontal flue is installed with the

correct fall to the boiler. Mark the offset (V) dimension and if required, mark the position of the gas and water pipes.

Remove the template.

5. Cut the hole for the flue (minimum diameter 127mm, see table (

) for wall thicknesses and flue diameters).

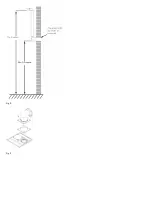

6. Drill and plug the wall as previously marked. Secure the wall plate (

7. Ensuring the wall plate is level both horizontally and vertically, drill and plug at least 5 securing positions at the top and bottom through the wall plate.

Utilising the slots available ensure the wall plate is square and secure to the wall (

).

8. Additionally drill 2 relief holes 10mm deep in the wall as shown on template (

9. Loosely route the condensate discharge pipe to the lower left hand side of the wall plate.

Fig. 19a

Summary of Contents for Main Heat 12

Page 8: ...Fig 3 Fig 4 Fig 5 Fig 6...

Page 38: ...Example 1 Example 2 Example 3...

Page 40: ...Fig E Fig F...

Page 51: ...Fig 31 Fig 32 Fig 33...

Page 55: ...Fig 35 Fig 36 page 39 12 2 Checking the Combustion 1 Follow the flow chart opposite...

Page 56: ......

Page 63: ...Fig 45 Fig 46...

Page 66: ......

Page 69: ...Fig 55 Fig 56 Fig 57 Fig 58...

Page 72: ...page 52...

Page 74: ...page 54...

Page 75: ...DRY FIRE...

Page 76: ...page 55 IGNITION LOCKOUT...

Page 77: ...page 56 OVERHEAT LOCKOUT...

Page 78: ...page 57 FAN LOCKOUT NOTE The fan is supplied with 325 Vdc...

Page 80: ...warranty This does not affect the customer s statutory rights page 62...

Page 82: ...page 63...