page 40

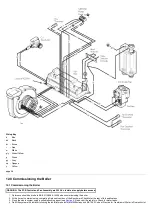

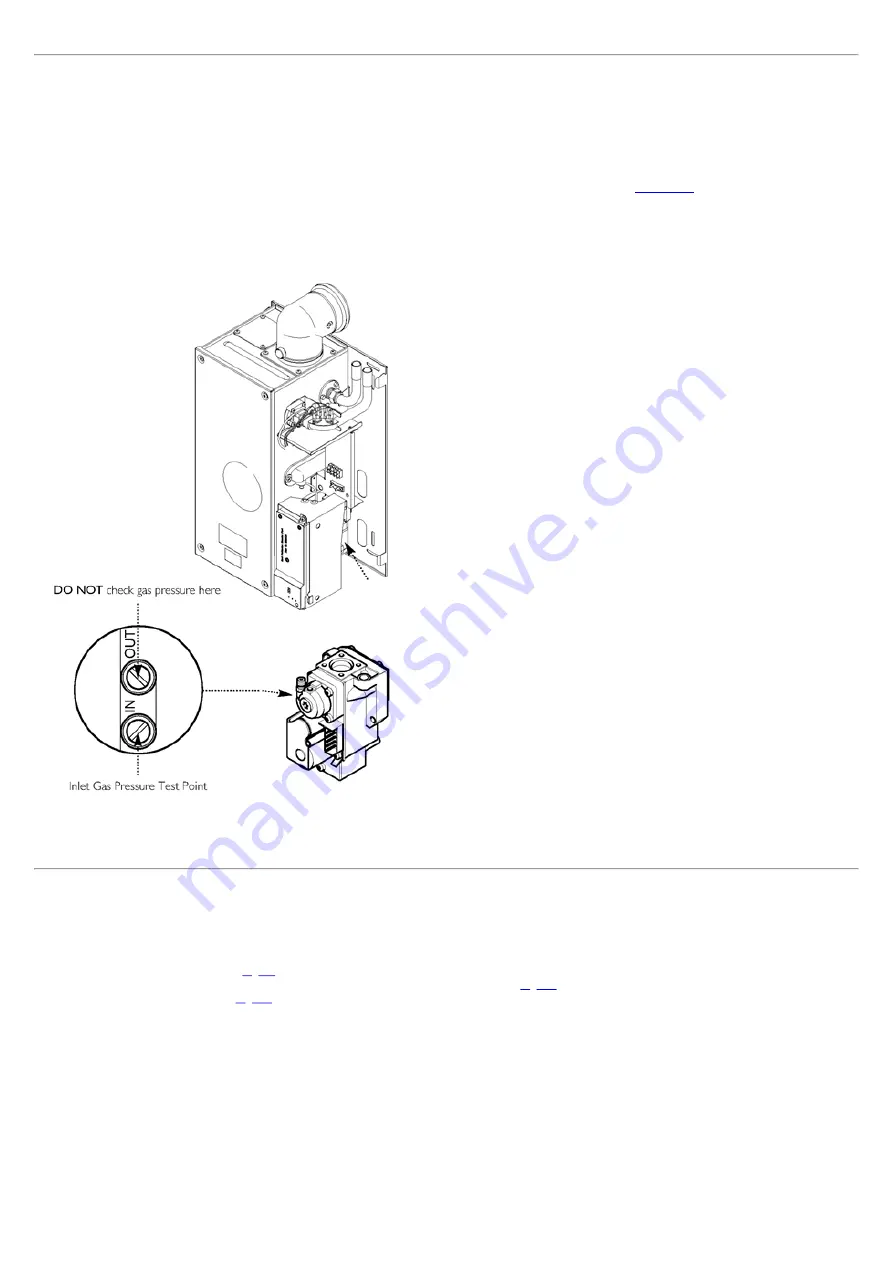

12.3 Check the Operational (Working) Gas Inlet Pressure

1. Ensure that all controls are calling for heat and maximum load is applied to the system.

2. With the boiler operating in the maximum rate condition check that the operational (working) gas pressure at the inlet gas pressure test point is in

accordance with B.S. 6798 & B.S. 6891.

3. Ensure that this inlet pressure can be obtained with all other gas appliances in the property working.

Measure the Gas Rate

4. With any other appliances & pilot lights turned OFF the gas rate can be measured. It should be as shown in

5. Carefully read and complete all sections of the Benchmark Commissioning Checklist at the rear of this publication that are relevant to the boiler and

installation. These details will be required in the event of any warranty work. The publication must be handed to the user for safe keeping and each

subsequent regular service visit recorded.

6. For IE, it is necessary to complete a "Declaration of Conformity"

to indicate compliance with I.S. 813. An example of this is given in I.S. 813 "Domestic

Gas Installations"

. This is in addition to the Benchmark Commissioning Checklist.

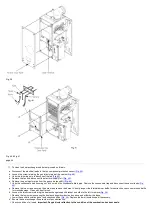

Fig. 36a

page 41

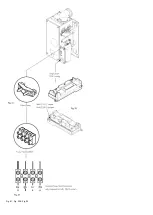

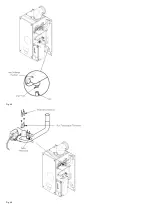

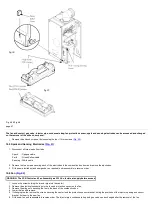

13.0 Fitting the Outer Case

13.1 Fitting The Outer Case

1. Position the outercase over the boiler engaging the lugs in the side flanges over the hooks on the wall plate. Break off top or bottom panel as required

to accommodate pipework runs (

).

2. Using the two screws supplied in the kit, secure the outercase to the combustion box (

3. Hinge up the lower door panel (

4. The "Important Ventilation Information"

label can be removed unless the appliance is installed in an unventilated compartment.

5. Carefully read and complete all sections of the Benchmark Commissioning Checklist at the rear of this publication that are relevant to the appliance

and installation. These details may be required in the event of any warranty work. The publication must be handed to the user for safe keeping and

each subsequent regular service visit recorded.

For IE, it is necessary to complete a "Declaration of Conformity"

to indicate compliance to I.S. 813. An example of this is given in I.S. 813 "Domestic

Gas Installations"

. This is in addition to the Benchmark Commissioning Checklist.

6. Instruct the user in the operation of the boiler controls. Hand over the User's Operating, Installation and Servicing Instructions, giving advice on the

necessity of regular servicing.

7. Demonstrate to the user the action required if a gas leak occurs or is suspected. Show them how to turn off the gas supply at the meter control, and

advise them not to operate electric light or power switched, and to ventilate the property.

8. Show the user the location of the system control isolation switch, and demonstrate its operation.

9. Advise the user that they may observe a plume of vapour from the flue terminal, and that it is part of the normal operation of the boiler.

10. Complete the label supplied with the inhibitor and stick to the inside of the boiler case. Detail of system treatment must be recorded in the Benchmark

Commissioning Checklist.

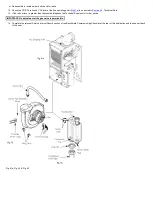

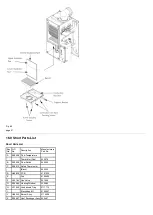

Summary of Contents for Main Heat 12

Page 8: ...Fig 3 Fig 4 Fig 5 Fig 6...

Page 38: ...Example 1 Example 2 Example 3...

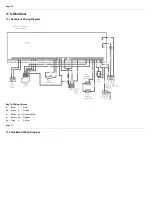

Page 40: ...Fig E Fig F...

Page 51: ...Fig 31 Fig 32 Fig 33...

Page 55: ...Fig 35 Fig 36 page 39 12 2 Checking the Combustion 1 Follow the flow chart opposite...

Page 56: ......

Page 63: ...Fig 45 Fig 46...

Page 66: ......

Page 69: ...Fig 55 Fig 56 Fig 57 Fig 58...

Page 72: ...page 52...

Page 74: ...page 54...

Page 75: ...DRY FIRE...

Page 76: ...page 55 IGNITION LOCKOUT...

Page 77: ...page 56 OVERHEAT LOCKOUT...

Page 78: ...page 57 FAN LOCKOUT NOTE The fan is supplied with 325 Vdc...

Page 80: ...warranty This does not affect the customer s statutory rights page 62...

Page 82: ...page 63...