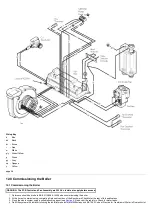

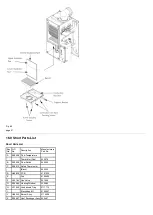

Fig. 50, Fig. 51 & Fig. 52

page 48

The removal of the fan is necessary to enable the changing of the injector pipe, condensate trap and gas valve (see

15.7 Injector Pipe (

)

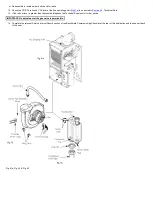

1. Remove the injector pipe by pulling out from the 'O' ring joint in the gas valve.

2. Fit the new injector pipe and reassemble in reverse order.

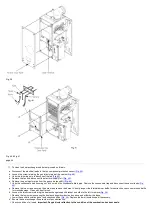

15.8 Gas Valve (

1. Remove the Control PCB (see

2. Isolate gas supply and disconnect the gas tap by removing the four screws.

3. Undo the case pressure pipe from the gas valve.

4. Disconnect the electrical plug from the gas valve.

5. Remove the fan (see

) and injector pipe.

6. Remove the two gas valve securing screws from inside the air box holding the gas valve.

7. Remove the gas valve from the airbox side.

8. Remove the aluminium spacer and its gasket from the gas valve.

9. Fit the aluminium spacer and gasket to the new valve.

10. 1Fit the new gas valve and reassemble in reverse order.

NOTE: Check for gas tightness after replacing gas valve.

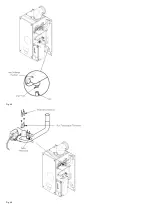

11. Check the CO/CO

2

ratio and CO

2

level at the flue sampling point (

) is as quoted in

, 'Technical Data'.

12. If the ratio or level is greater than that quoted, telephone the Technical Enquiries for further advice.

IMPORTANT: No adjustment of the gas valve is permissible.

Fig. 53

Summary of Contents for Main Heat 12

Page 8: ...Fig 3 Fig 4 Fig 5 Fig 6...

Page 38: ...Example 1 Example 2 Example 3...

Page 40: ...Fig E Fig F...

Page 51: ...Fig 31 Fig 32 Fig 33...

Page 55: ...Fig 35 Fig 36 page 39 12 2 Checking the Combustion 1 Follow the flow chart opposite...

Page 56: ......

Page 63: ...Fig 45 Fig 46...

Page 66: ......

Page 69: ...Fig 55 Fig 56 Fig 57 Fig 58...

Page 72: ...page 52...

Page 74: ...page 54...

Page 75: ...DRY FIRE...

Page 76: ...page 55 IGNITION LOCKOUT...

Page 77: ...page 56 OVERHEAT LOCKOUT...

Page 78: ...page 57 FAN LOCKOUT NOTE The fan is supplied with 325 Vdc...

Page 80: ...warranty This does not affect the customer s statutory rights page 62...

Page 82: ...page 63...