8.0 Emergency

11

© Baxi Heating UK Ltd 2011

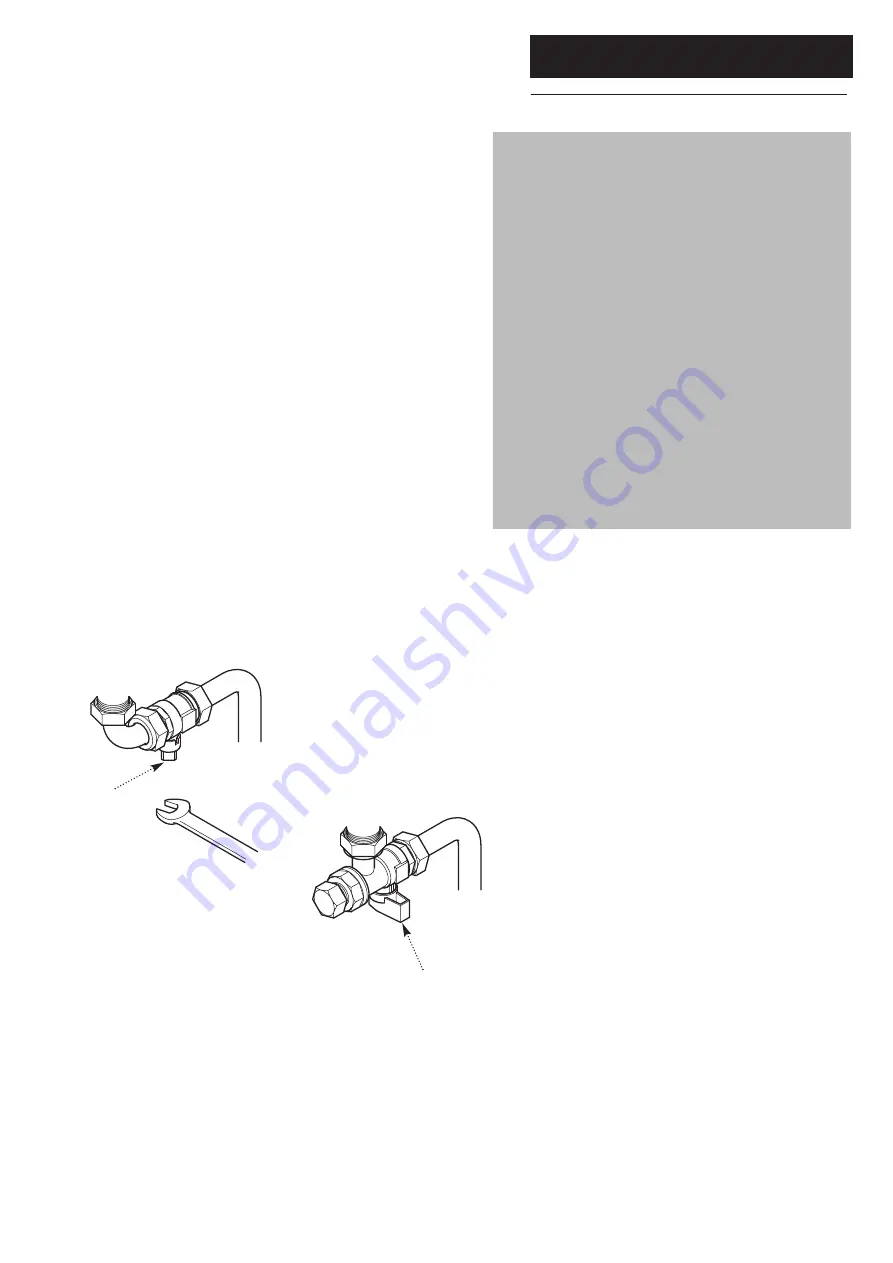

Gas Tap

Heating Flow, Heating

Return and Mains Water

Inlet Isolating Valves

Fig. 6

Fig. 7

In an Emergency

If a water or gas leak occurs or is suspected, the boiler can

be isolated at the inlet valves as follows;

1. Using a suitable open ended spanner, turn the square

nut on the gas tap through 90° (

1

/

4

turn) to isolate the gas

supply at the boiler (Fig. 6).

2. The water isolating valves are positioned under the

boiler and can be closed by turning their taps to the right

towards the wall (Fig. 7).

3. Call your Installer or Service Engineer as soon as

possible.

If you smell gas

Do not operate light switches

Do not operate any electrical equipment

Do not use a telephone in the hazardous area

Extinguish any naked flame and do not smoke

Open windows and doors in the hazardous area

Turn off the gas supply at the meter

Warn any other occupants and vacate the premises

Telephone the National Gas Emergency Service on:-

0800 111 999

Faulty boiler

If it is known or suspected that a fault exists

on the boiler, it must not be used until the fault

has been corrected by a competent person.

Warning !

Supplied by HeatingSpares247.com