8.0

INSTALLATION

20

8.4

Fitting The Boiler

1. Lift the boiler using the lower edges. Engage the

slots at the top rear of the boiler on the wall plate

hooks (Fig. 23).

2. Ensure that the boiler is level and sits against the

wall.

3. Take the two steel washers and remaining screws.

Using the previously drilled and plugged holes, secure

the bottom of the boiler to the wall (Fig. 24).

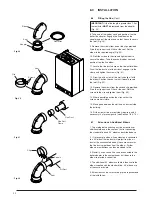

4. Remove the elbows, valves and sealing washers

from the packaging. The 3/4 in valve with internal filter

must be fitted to the central heating return. The filter is

visible through the branch connection of the valve.

5. Using the sealing washers provided connect the

valves to the heating flow and return, and the cold

water inlet.

6. Connect the elbows to the gas service cock and hot

water outlet pipe, and then connect the elbows to the

boiler. Connect the elbows with flared ends to the

valves.

7. Ensure that the sealing washers are used on all

connections. The rubber washers must be used on the

gas connections.

8. The gas and water supplies, central heating flow

and return and domestic hot water flow can now be

connected.

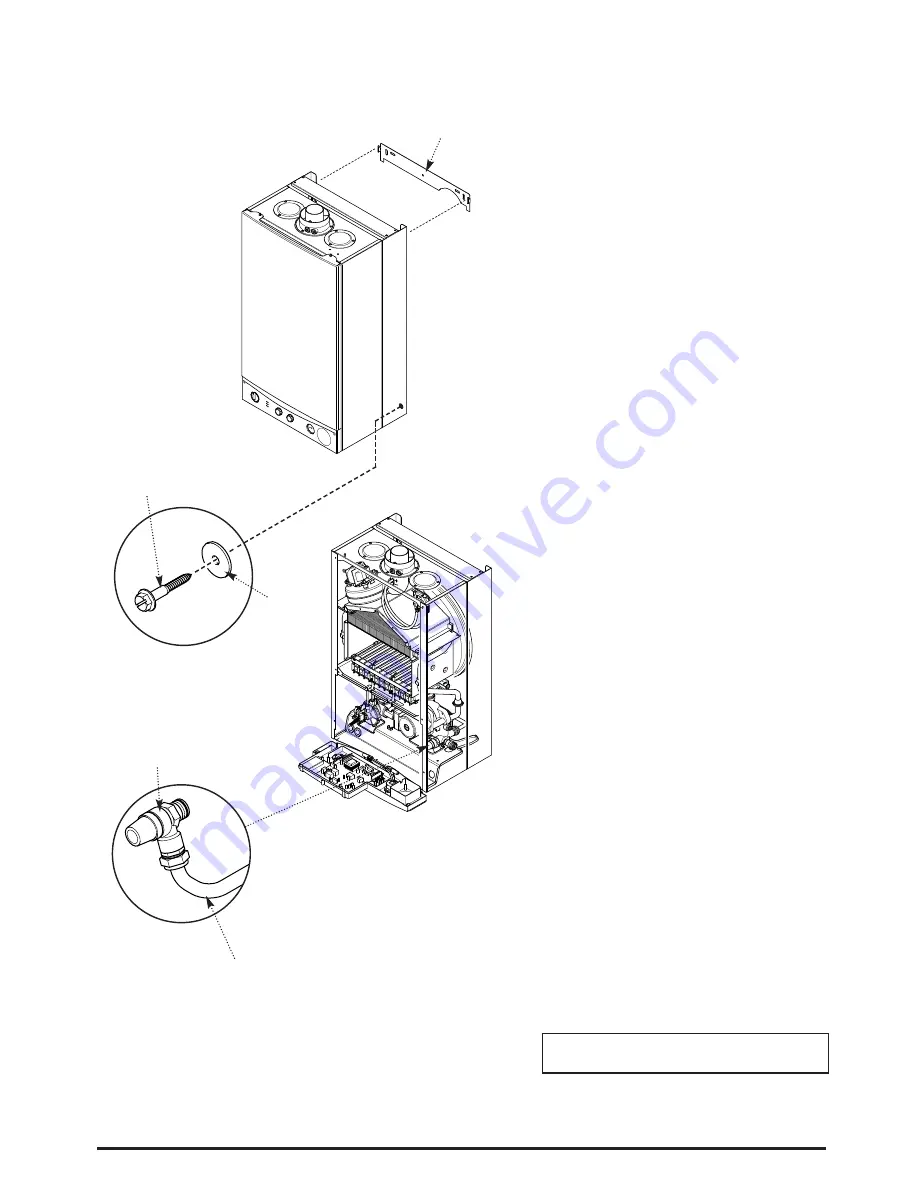

8.5

Fitting the Pressure Relief

Discharge Pipe

(Fig. 25)

1. Remove the discharge pipe from the kit.

2. Determine the routing of the discharge pipe in the

vicinity of the boiler. Make up as much of the pipework

as is practical, including the discharge pipe supplied.

3. The pipework must be at least 15mm diameter and

run continuously downwards to a discharge point

outside the building. See section 6.7 for further details.

4. Using one of the sealing washers, connect the

discharge pipe to the adaptor and tighten the nut.

5. Complete the discharge pipework and route it to the

outside discharge point.

IMPORTANT:

Make all soldered joints before

connecting to the pressure relief valve.

Fig. 25

Fig. 23

Fig. 24

Pressure Relief Valve

Securing Screw

Washer

Wall Plate

Discharge Pipe

Summary of Contents for Combi 24 HE

Page 45: ...45 16 0 NOTES ...