Maintenance and servicing

27

9

Maintenance and servicing

Regular checks of the pellet heating system are a prerequisite for reliable, efficient and environment-friendly operation.

9.1 Maintenance

The maintenance, boiler cleaning and cleaning of flue gas connection it is necessary at least once a year. For PE(S)

36-56 it is necessary in any case at least every 2000 operating hours. Pellets which produces tendentially more

slagging (ash melting point <1300 ° C) and pellets with higher bulk density (> 650kg) leads to additional cleaning of the

burner plate at regular intervals.

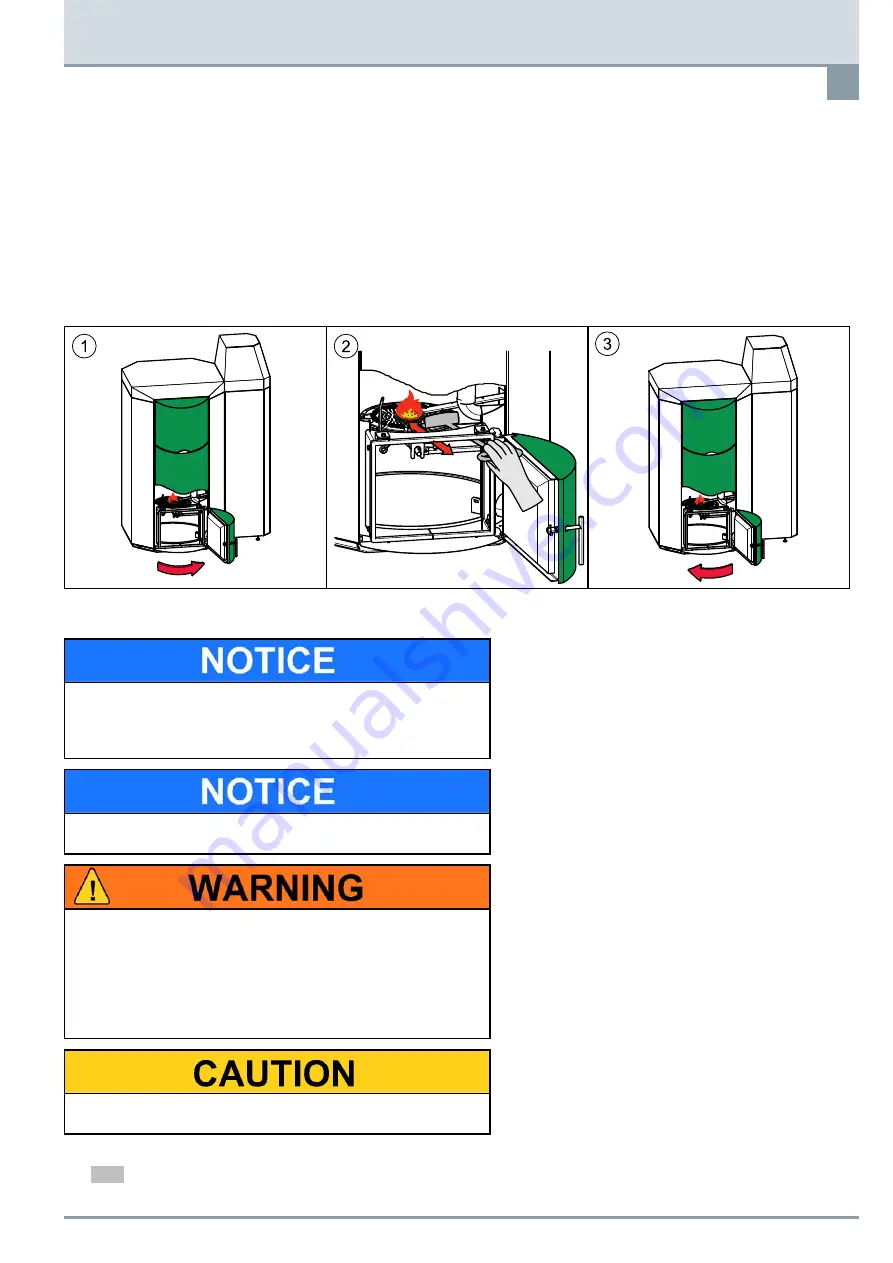

9.2 Cleaning the boiler every year

The pellet boiler is equipped with an automatic cleaning

system that cleans the heat exchanger every day. In

addition, you need to clean the boiler manually once a

year before the start of the heating season.

Cleaning of the pellet boiler has to be performed from a

authorized service technician at least every third year.

Risk of burns

Do not clean the boiler until it has been allowed to cool

down.

Switch off the heating system at least 6 hours before

opening the boiler.

Switch off the main switch before starting any maintenance

work on the system.

Risk of cut injuries due to sharp edges

Use gloves.

Note

Check first of all, if all seals are in a good condition and the doors closes tightly.

PE 149 USA 4.1

Operating Manual PE 12-32

Summary of Contents for Pellematic PE 12-20

Page 21: ...Operating the pellet boiler 21 Setting date and time PE 149 USA 4 1 Operating Manual PE 12 32...

Page 32: ......

Page 33: ......