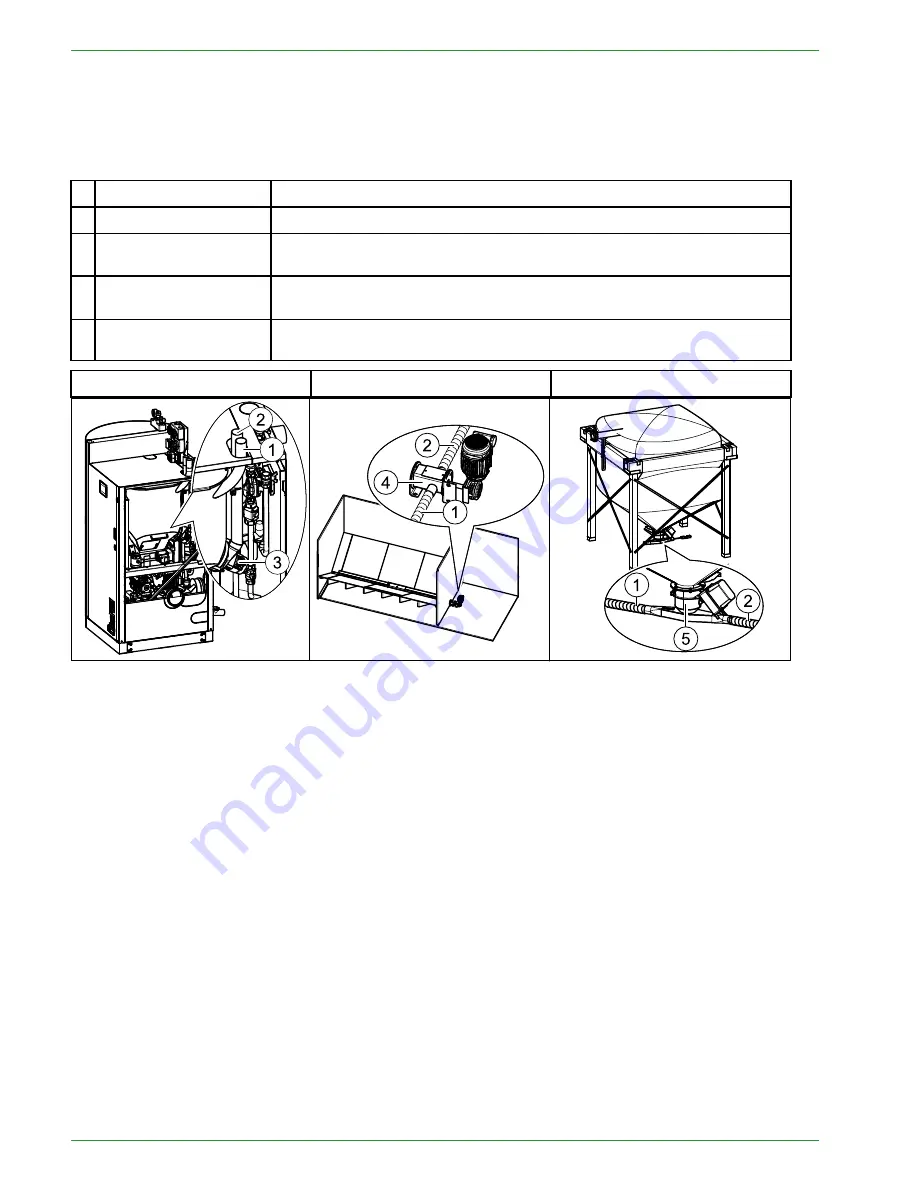

8.2 Pellet suction system

The pellet suction system consists of the pellet hose, air hose and a suction turbine. The suction vacuum turbi-

ne in the hopper conveys pellets in the pellet line from the storage room or fabric tank to the hopper.

Key components of pellet suction system

1

Pellet- Suction hose

Line from the storage room auger or fabric tank to the hopper.

2

Pellet- Return air hose

Line from the suction fan to the storage room auger or fabric tank.

3

Suction fan / Vac

turbine

Located beside the hopper behind the Pellet boiler burner housing.

4

T-piece at end of stora-

ge system auger

Located at front end of the storage room auger, outside the storage

room.

5

Suction Metering

Switch

Located underneath the fabric tank.

Pellet boiler

Version A pellet storage room

Version B fabric tank

8.2.1 Assembly of the vacuum system

The pellet hose and the air hose are flexible spiral hoses made out of plastic. A copper braid embedded in the

hose dissapates static charge when properly grounded.

Assembly guidelines

•

Bending radius:

The hose should be as short as possible and with as few curves as possible. Bending radius

may never be smaller than 12 inches.

•

Vertical Lift:

Max difference in height = 10 feet. A difference in height of up to 10 feet can be overcome at

one time.

Larger differences in height must by interrupted with a minimum 4 foot flat section of hose for the pellets.

•

Impact protection / Velocity Control:

The spiral hose can be run no more than 13 feet in a straight line.

Small bends particularly in front of curves reduces the abrasion of the spiral hose by controlling pellet

velocity.

•

Installation in the soil and openings:

When burying hose in the ground, it must be inside a protective pipe

such as electrical conduit that is 4 inch in diameter. This pipe must be sealed and may not make any arc mo-

re than 15°.

•

Hose to be Air Tight:

For trouble free operation, the vacuum system must be 100% air tight at all

connections!

All connection points must be secured with a hose clamp.

•

Grounding:

The hoses are provided with a copper braid which helps the hose dissipate static charge. In or-

der to ensure this function, copper braid must be connected to a known ground point at each end.

PE 608 USA_FA 2.1

22

Pellet suction system