22

Kleiss MCS60-1016 System Manual v.15 June 2020

|

www.MainlineControlSystems.com

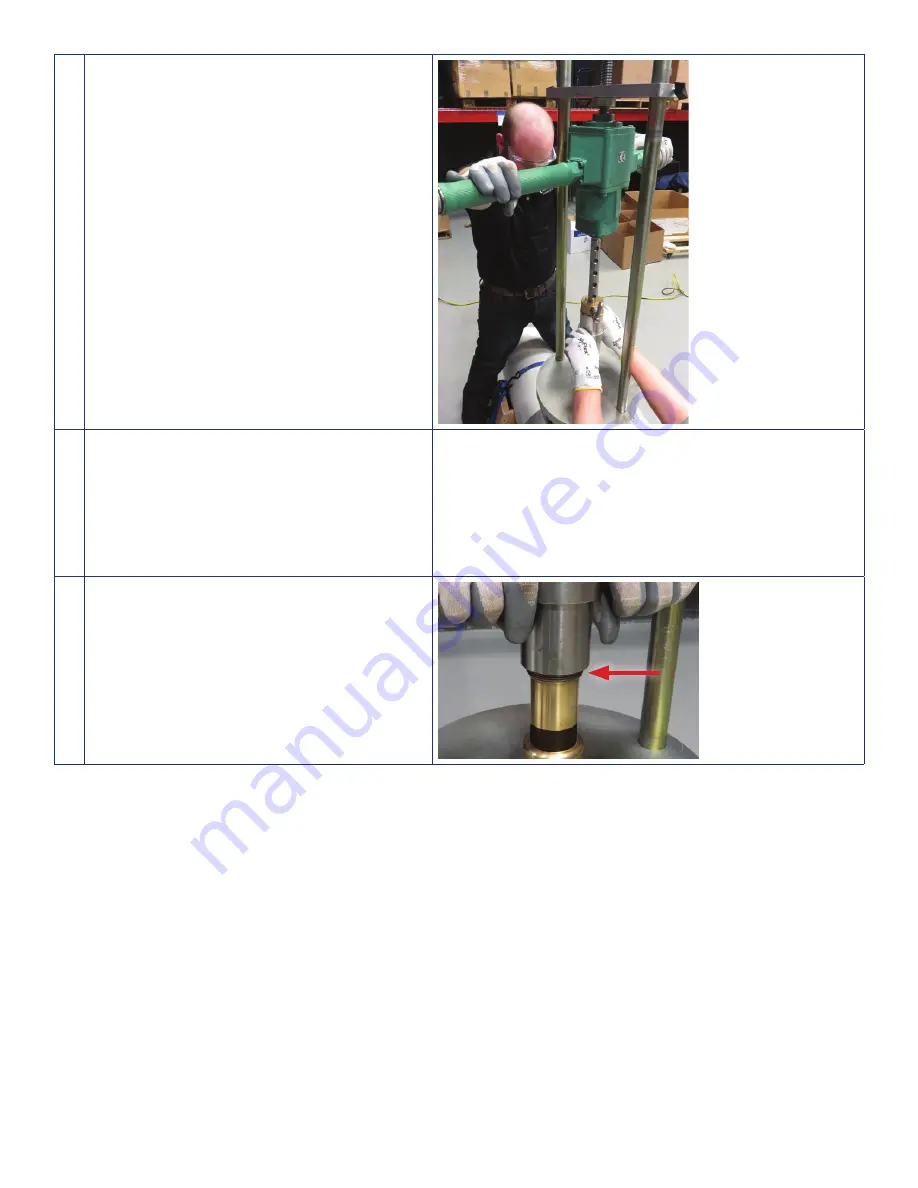

Use the air motor to turn the drilling rod

clockwise.

Make certain the drilling direction is

set in the down position.

While the drilling rod is rotating clockwise slowly

hand feed the cutter downward by turning the feed

tube handles clockwise to cut the pipe.

(Do not feed the cutter too quickly and cause a

bind and potential cutter breakage. Especially on

steel and cast iron.)

Continue to lower the feeding rod from above

with bridge as the air motor lowers to keep the air

motor centered and stable.

The tapping procedure is finished when the

drilling rod can rotate without any resistance.

NOTE: You will feel less resistance twice - once

in the beginning when the pilot drill has perforated

the pipe wall and secondly when the cutter is

completely through.

To retract cutter and coupon, continue spinning

the drilling rod clockwise while rotating the feed

tube counterclockwise until you have reached the

starting position with 3 threads exposed.

(NEVER turn the drilling rod counterclockwise.

This can damage the cutter.)