1

PB

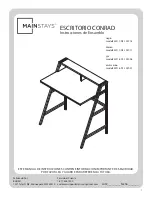

model# MS17-D4-1007-16

model# MS17-D4-1007-17

model# MS18-D1-1007-06

model# MS18-D1-1007-07

Lot#_________Date________

Customer Service:

1.877.436.7290

customersupport@tenspringstreet.com

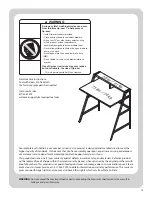

THIS INSTRUCTION BOOKLET CONTAINS

IMPORTANT

SAFETY INFORMATION.

PLEASE READ AND KEEP FOR FUTURE REFERENCE.

black

white

gray

navy

Manufactured By:

BDDMI

1321 Tyler St NE, Minneapolis, MN 55413

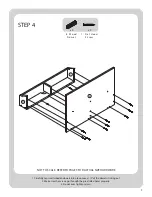

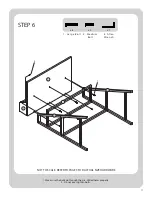

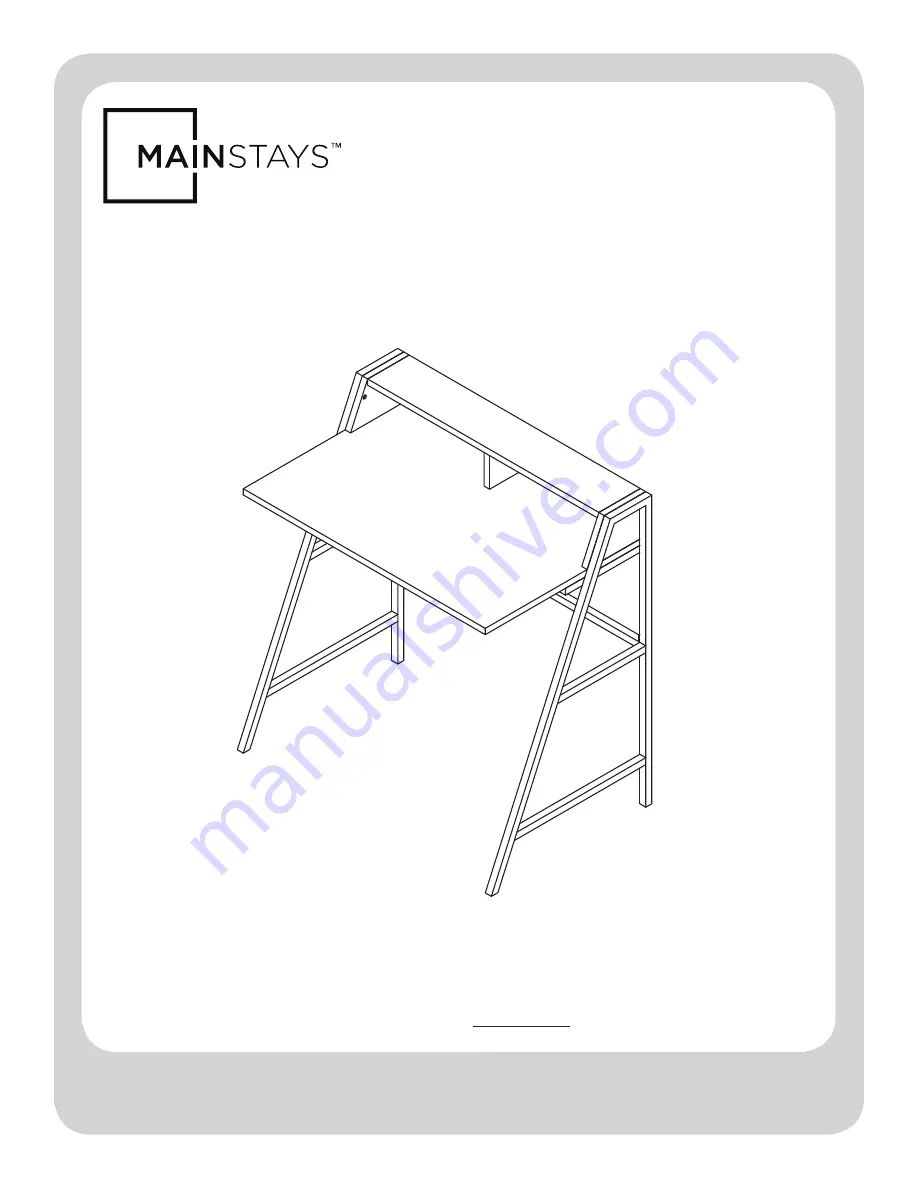

Assembly Instructions

CONRAD DESK WITH HUTCH