Summary of Contents for MJ-9000V

Page 1: ...1 MJ9000V TECHNICAL MANUAL MJ9900 Installation dimension ...

Page 7: ...7 ...

Page 9: ...9 ...

Page 11: ...11 ...

Page 13: ...13 ...

Page 15: ...15 ...

Page 16: ...16 ...

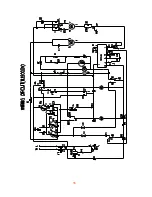

Page 25: ...25 Fan Heat element ...

Page 27: ...27 ...