2

Majestic

®

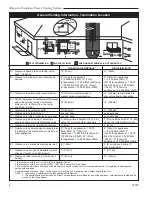

Fireplaces Power Venting System

51810

Installation Instructions

General information and instructions for the power vent

system model No. PVS-1.

NOTE: The PVS-1 will only

work in conjunction with a VN Gas Valve P/N 57588

or VP Gas Valve P/N 57587.

1. This power vent system must be installed by a quali-

fied installer in accordance with all applicable local

codes and with the current installation codes for gas

burning appliances CSA-B149.1 in Canada or ANSI

Z223.1/NFPA 54 in the U.S.A.

Electrical connections and grounding must be in ac-

cordance with the Canadian Electrical Code, C22.1

Part 1 and in U.S.A., National Electrical Code ANSI/

NFPA70 and/or local codes where applicable.

2. This device must be installed by a qualified profes-

sional installer in accordance with these instructions.

If improperly installed, a hazardous condition such

as an explosion or carbon monoxide poison could

result.

3. The Power Vent System #PVS-1 has been certified

by CSA to be installed as a component part and is

for use only with fireplace models listed in the front

page of this manual. Certification is cancelled if

used with other than listed products.

4. Plan the vent system so that code required distanc-

es are maintained from plumbing and wiring.

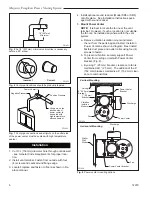

5. The Power Venter motor shaft must be mounted

horizontally to ensure proper operation of the fan

pressure proving switch and to prevent motor bear-

ing wear.

6. Flue gas temperatures must not exceed 470ºF at

Power Venter inlet. Ambient temperature must not

exceed 104ºF.

7. Disconnect power supply when making wiring con-

nections or when working around the fan blade and

motor. Failure to do so may result in severe personal

injury and equipment damage.

8. Make certain the power source is adequate for the

fan motor requirements. Do not add the Power Ven-

ter to a circuit where the total load is unknown.

9. This Power Venter System #PVS-1 shall be installed

with Sound Reducer Kit Nos. SR 4 for fireplaces with

a 4” (102 mm) flue collars and SR 5 for fireplaces

with 5” (127 mm) flue collars. See INSTALLATION

RESTRICTIONS Page 5.

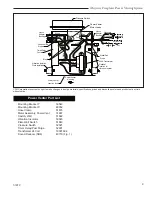

Power Vent System Parts and Description

1. Fan Assembly - comes complete with 6’ (1.8 m)

power cord for plugging into a standard house

receptacle. The system is completely pre-wired and

includes the pressure switch and 24 volt transformer.

2. 24 Volt Wiring Harness - a 40’ (12m) wiring harness

with plug-in connectors. Eliminates costly time con-

suming electrical installations.

3. Vent Terminal - the device which exhausts flue

gases into the atmosphere.

4. Fan Mounting Bracket - to secure the fan in a vibra-

tion-free mode so as to reduce vibration through the

pipes.

5. Flex-Connector - an additional device to reduce

vibration and noise through the pipes. It is mounted

to the negative inlet side of the fan.

6. Approved 4” (102 mm) diameter insulated aluminum

flex liner, 4” (102 mm) diameter B-Vent* or 4” (102

mm) diameter single wall metal vent connector.

7. Assorted clamps, connectors and wall mounting

brackets.

General Venting Information

Always consult your local codes and authorities, in

the absence of such codes, follow the current installa-

tion codes for gas burning appliances CSA-B149.1 in

Canada or ANSI Z223.1/NFPA 54 in the US.

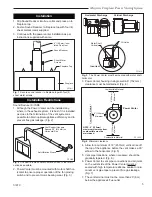

1. Clearance to Combustible Materials:

•

1” (25 mm) for insulated single wall vent or

flexible vent pipe.

•

6” (152 mm) for single wall fan housing.

•

1” (25 mm) for fan motor.

•

1” (25 mm) for B-Vent.*

•

6” (152 mm) for single wall vent or flexible vent

pipe.

* B-Vent can only be used on the negative side of

the power venter - between the appliance and

the power venter - and insulated flexible liner or

single wall vent on the outlet side of the power

venter. To reduce fan noise or condensation,

CFM Corporation recommends all venting pipes

be insulated with a minimum of 1” (25 mm) fiber-

glass insulation.

2. Total allowable system length is 100’ (30 m) of

straight pipe. Minimum allowable system length is 5’

(1.5 m).

NOTE:

Deduct 10’ (3 m) for each 90° elbow and 5’

(1.5 m) for each 45° elbow.

Example:

An installation requires 30’ (9 m) of

straight pipe with 45° and three (3) 90° elbow.

Straight pipe

30’ (9 m)

45º Elbow (1) 5’ (1.5 m)

90º Elbow (3) 30’ (9 m)

TOTAL

65’ (19.5 m)

Total equivalent pipe length = 65’ (19.5 m)