6

Majestic

®

Fireplaces Power Venting System

51810

FP1421

Min. vertical rise

11/25/03 djt

18” (457mm)

Minimum

FP1421

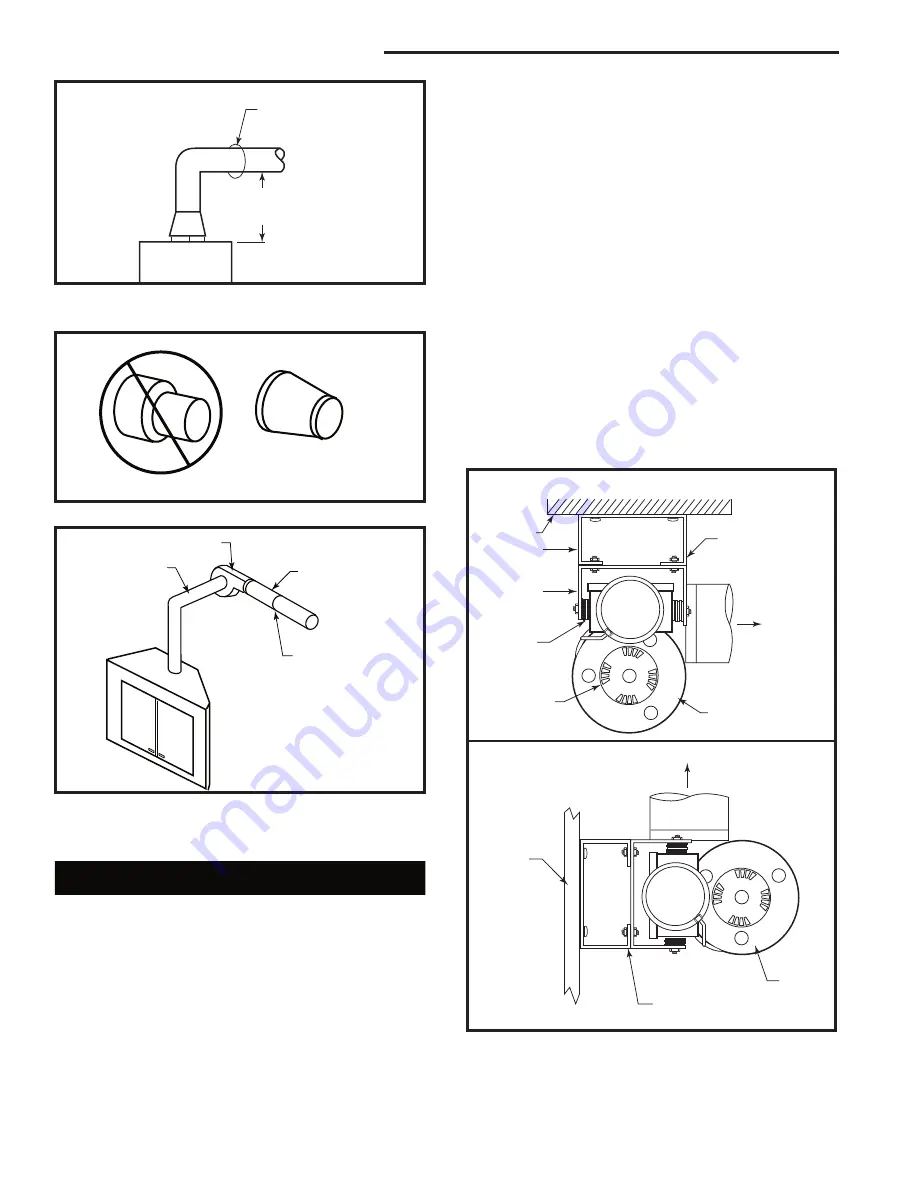

Fig. 5

An 18” (457mm) minimum vertical rise is necessary

before a 90° elbow.

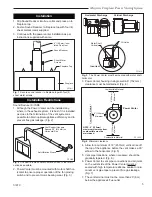

FP1422

pipe transitions

11/25/03 djt

Negative Pressure

Power Venter

Positive Pressure

All seams on the

positive side of

power venter to

be sealed with

high temperature

silicone sealant.

FP1422

Fig. 7

Vent pipe connections and all joints on the outlet side

of the power venter must be sealed with high temperature

sealant.

FP1423

pipe transitions

11/25/03 djt

Incorrect

Correct

FP1423

Fig. 6

Vent pipe transitions should be gradually tapered.

Installation

1. Cut 6

¹⁄₄

” (159mm) diameter hole through outside wall

- see General Code Requirements for proper loca-

tion.

2. Install vent terminal. Fasten from outside with four

(4) screws and caulk around flange edge.

3. Locate fireplace and fasten to floor as shown in fire-

place manual.

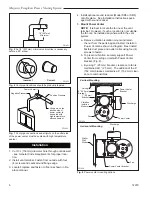

FP1425

horizontal mounting

11/25/03 djt

FP1424

vertical mounting

11/25/03 djt

Ceiling

6” (152 mm)

Bracket

1” (25 mm)

Bracket

Vibration

Isolation

Mounts

Fan

Power Venter

Discharge

Power Venter

Bracket

Discharge

Fan

Power Venter Bracket

Wall or

Wall

Studs

Horizontal Mounting

Vertical Mounting

FP1425

Fig. 8

Power venter mounting options.

FP1424

4. Install optional sound reducer (Model SR5 or SR4)

onto fireplace. See Installation Instructions pack-

aged with sound reducer.

5.

Mount Power Venter

NOTE:

It is best to locate the fan near the vent

terminal. However, if such a location is not suitable,

the fan can be installed anywhere within the vent

system.

a. Remove vibration isolation mount and retain

the nut from the parts bag and install. Install on

Power Venter as shown in diagram. Next install

flexible duct piece and outlet collar using four (4)

screws to fasten.

b. To prevent vibration, securely support Power

Venter from ceiling or joist with Power Venter

bracket. (Fig. 8)

c. By using 1” (25 mm) bracket, clearance to fan is

maintained at 1” (25 mm). The addition of the 6”

(152 mm) bracket, maintains a 6” (152 mm) clear-

ance to combustibles.