8

Majestic

®

Fireplaces Power Venting System

51810

Operation and Checking the Draft

1. Insofar as is practical, close all doors, windows and

air inlets to the building. Turn on all exhaust fans

(range hood, bathroom exhaust, etc.) so they will

operate at maximum speed.

2. Place appliance into operation. See fireplace

manual for gas start up information. Once pilot has

been lit and gas valve has been set open, activate

power switch, or where applicable, adjust thermostat

so the appliance will operate continuously. At this

point the fan will start up and once air flow has been

proven the main burner will start.

3. After allowing appliance to operate for five (5) min-

utes, test for spillage at the draft hood relief opening

or at fireplace front opening.

Checking the Draft.

Allow the vent connected gas

utilization equipment to operate for several minutes.

Then check to see that the combustion products

are going up the chimney or gas vent properly, by

passing a lighted match or taper around the edge

of the relief opening of the draft hood. If the chim-

ney or gas vent is drawing properly, the smoke

from the match flame will be drawn into the draft

hood or opening. If smoke is not drawn in, then the

combustion products are escaping from the relief

opening into the room. Under these conditions, the

equipment must not be operated until proper adjust-

ments or repairs are made to provide adequate draft

through the chimney or gas vent.

4. Next, turn on all other fuel-burning appliances within

the same room so they will operate at their full input.

Repeat Step C above, checking the draft on each

appliance.

5. The Air-Flow Adjustment on the Power Venter is fac-

tory set for maximum air flow. Operating a properly

sized Power Venter at maximum setting will assure

that combustion gases are safely removed to the

outside. If the Power Venter has excess venting

capacity than what is required for this application,

operating the Power Venter with the Air-Flow Adjust-

ment at the maximum setting may draw more dilu-

tion air than necessary.

The Air-Flow Adjustment may be set by use of a

combustion analyzer, inclined manometer or draft

gauge. Alternatively, the Air-Flow adjustment can be

set using a smoke candle or taper, as follows:

a. With exhaust fans operating, air inlets closed and

all appliances firing (as instructed above), hold

lighted match or taper around the edge of the re-

lief opening of the draft hood or fireplace opening.

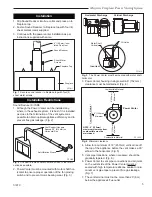

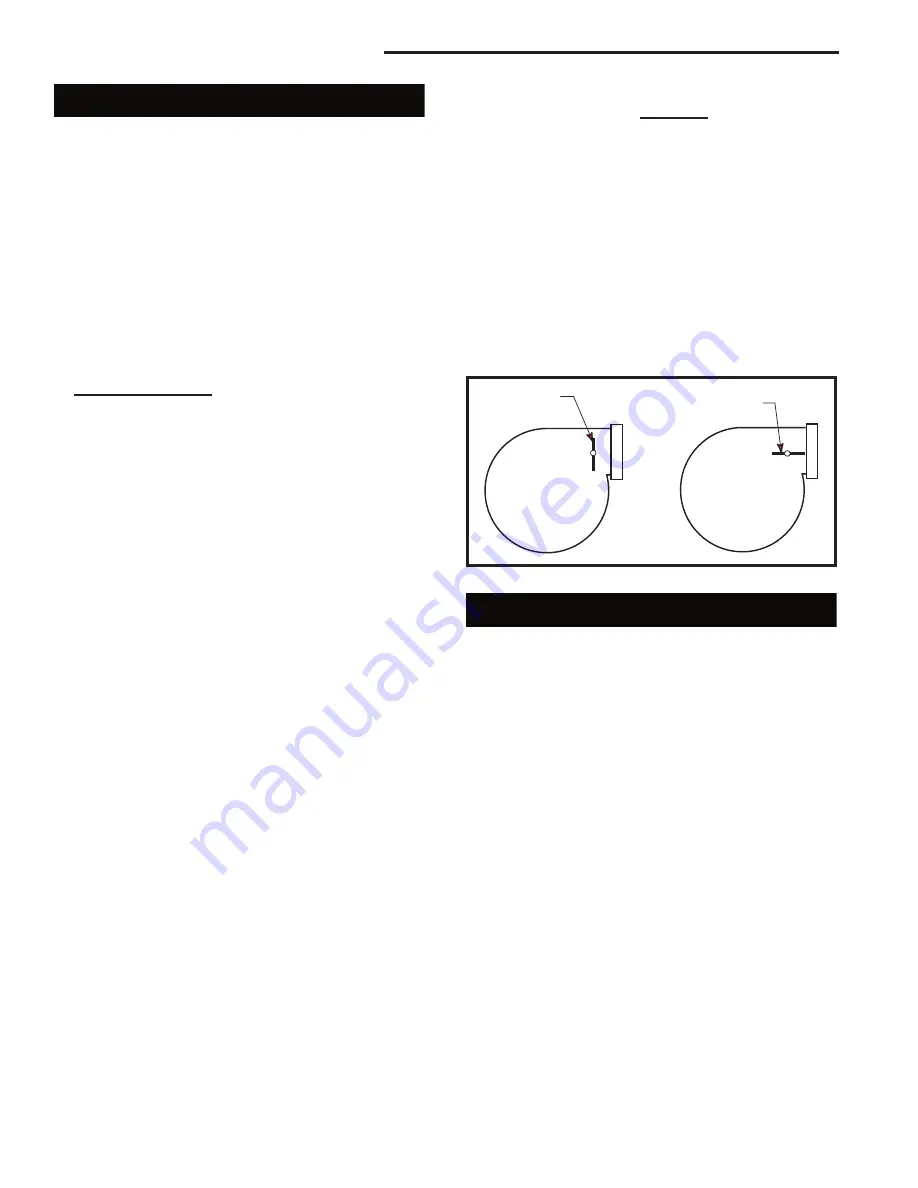

b. Set Air-Flow Adjustment by loosening locknut and

turning rod handle.

CAUTION: HANDLE MAY

BE HOT

, use pliers to move handle. Position of

rod handle on outside of Power Venter housing

indicates position of Air-Flow Adjustment inside

housing.

c. Using pliers, move handle towards minimum draft

setting until spillage is detected at relief opening,

then re-open Adjustment just enough to eliminate

spillage.

d. Lock Adjustment at desired setting by tightening

locknut.

e. Return doors, windows exhaust fans and fire-

place dampers to their previous condition of use.

f. Turn off appliances started in Step 4 above.

FP1427

damper

11/25/03 djt

Damper Closed

Damper Open

FP1427

Fig. 10

Adjustable damper control.

Maintenance

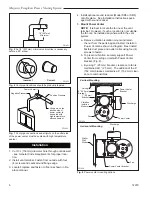

The Power Venters must be inspected semi-annually.

Points of inspection are:

1. Motor - Motor must rotate freely. Oil every six

months of operation with four (4) drops of SAE 20

oil.

2. Wheel - Wheel must be clean of soot, ash or any

other coating which inhibits rotation or air flow. Re-

move all foreign material from vent system before

operation.

3. Pressure Switch - Pressure Switch must operate

freely. Verify proper operation by observing Opera-

tion Sequence at least every six months.