20

53D0419

Designer Series Gas Fireplaces

•

If a 90° elbow is used in the horizontal vent run, the horizontal

vent length is reduced by 36" (914 mm).

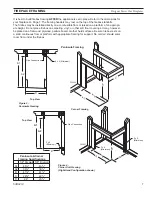

Figure 25.

This does

not apply if the 90° elbows are used to increase or redirect a

vertical rise.

Figure 25

Example:

According to the vent graph,

Figure 22

, the maximum

horizontal vent length in a system with a 7.5' vertical rise is 20’

(6 m) and if a 90° elbow is required in the horizontal vent it must

be reduced to 17' (5.2 m). Refer to Page 17 “How to Use Vent

Graph.”

In

Figures 26 and 27

, Dimension A plus B must not be greater

than 17' (5.2 m).

•

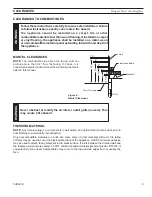

The maximum number of 45° elbows permitted per side wall

installation is two (2). These elbows can be installed in either

the vertical or horizontal run.

•

For each 45° elbow installed in the horizontal run, the length

of the horizontal run MUST be reduced by 18" (45 cm). This

does not apply if the 45° elbows are installed on the vertical

part of the vent system.

•

The maximum number of elbow degrees in a system is 270°.

Figure 27

VENTING INSTaLLaTIoN

hoRIZoNTaL TERMINaTIoN CoNFIGuRaTIoN

(Continued)

7’6”

A

B

90°

FP2305

run reduction

Figure 25 -

Horizontal Run Reduction

FP2305

A

10’

B

7’

7’6”

FP2306

max vent run elbows

Figure 26 -

Maximum Vent Run with Elbows

Example:

Elbow 1 = 90°

Elbow 2 = 45°

Elbow 3 = 45°

Elbow 4 = 90°

Total Angular Variation = 270°

A + B = 17' Maximum

90° Elbow = 3'

FP2306

Figure 27 -

Maximum Elbow Usage

1 + 2 + 3 + 4 = 270°

1

2

3

4

1

2

3

4

FP2307

max elbows

FP2307