Majestic • MER36N, MER36L, MER42N, MER42L Owner’s Manual • 2595-981 Rev. B • 5/23

20

With proper installation, operation, and maintenance your gas appliance will provide years of trouble-free service. If you do

experience a problem, this troubleshooting guide will assist a qualified service technician in the diagnosis of a problem and

the corrective action to be taken. This troubleshooting guide can only be used by a qualified service technician. Contact

your dealer to arrange a service call by a qualified service technician.

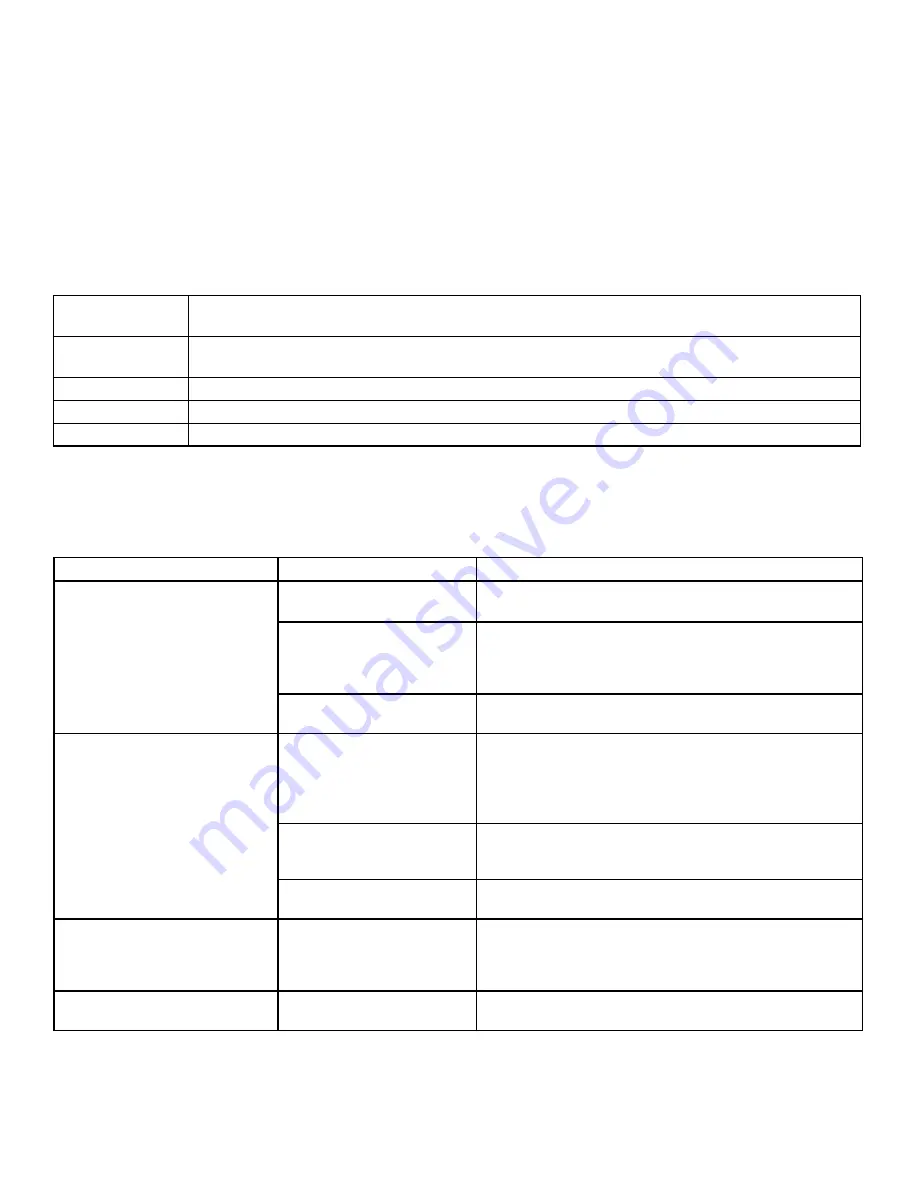

C. Troubleshooting

IntelliFire Touch

Symptom

Possible Cause

Corrective Action

Pilot won’t light, module clicks but

no spark 90 sec, 3 Red/1 Green

Lock out.

Incorrect wiring.

Verify ‘S’ (White) sense wire and ‘I’ (orange) ignitor wire are

connected to correct terminals on

IFT-

ECM.

Loose connections or electrical

shorts in wiring.

Verify no loose connections or electrical shorts in wiring from

module to pilot assembly. Verify wire insulation is not dam-

aged. Verify wires are not grounding out to chassis, pilot burn-

er, or any other metal object. Replace any damaged wires.

Ignitor gap is too large.

Verify spark gap is approximately 0.095” (2.41 mm) to 0.135”

(3.43 mm).

Pilot won’t light, there is no noise

or spark.

No AC power, AC/DC adaptor

faulty, backup batteries (if

being used) depleted,

IFT-

ECM slider switch in OFF

position.

Verify

IFT-

ECM slider switch is in ON or REM position. Verify

AC power available to junction box. Verify AC/DC adaptor is

plugged into junction box and ECM. Verify AC/DC adaptor out-

put voltage is between 5.7-6.3 Vdc. If battery pack is used,

check battery pack voltage is >4.2 V (if not, replace batteries).

Shorted or loose connection

in system wiring or wiring

harness.

Verify system wiring configuration. Remove and reinstall wir

-

ing harness that plugs into module. Check continuity of wires

in valve wiring harness. Replace any damaged components.

Poor or no system ground.

Verify black ground wire in valve harness is connected to metal

chassis of fireplace.

Pilot won’t light, there is no noise

or spark, 2 Red/1 Green Lockout.

Pilot solenoid not detected.

Check if valve harness orange wire is connected to pilot so

-

lenoid valve. Check pilot solenoid resistance, nominal is 40

ohms. If open or shorted, replace valve. Check valve harness

wire continuity, if open replace 6-pin harness.

Pilot won’t light, there is no noise

or spark, 2 Red/2 Green Lockout.

Spark coil failure.

Replace ECM.

ECM LED Error

Codes

Description

3 Red: 1 Green

IFT-RC400 error message: ‘Appliance Safely Disabled’, pilot sparks for 90 sec, no flame

rectification.

2 Red: 1 Green

IFT-RC400 display: ‘Error Pilot Flame’, pilot valve solenoid not detected.

2 Red: 2 Green

Sparking feedback signal error, spark coil failure.

5 Red: 1 Green

IFT-RC400 display: ‘Error Power Vent’ (if installed).

Error Codes:

Troubleshooting:

See Troubleshooting matrix for more detail on Lock-out Error Codes, Possible Causes and Corrective Actions.

Note to Qualified Service Technician:

Additional resources including troubleshooting guides and service videos are

available through Hearth & Home Technologies. Contact your dealer or access resources through your myhht.com account.