Part 3:

Operating Instructions

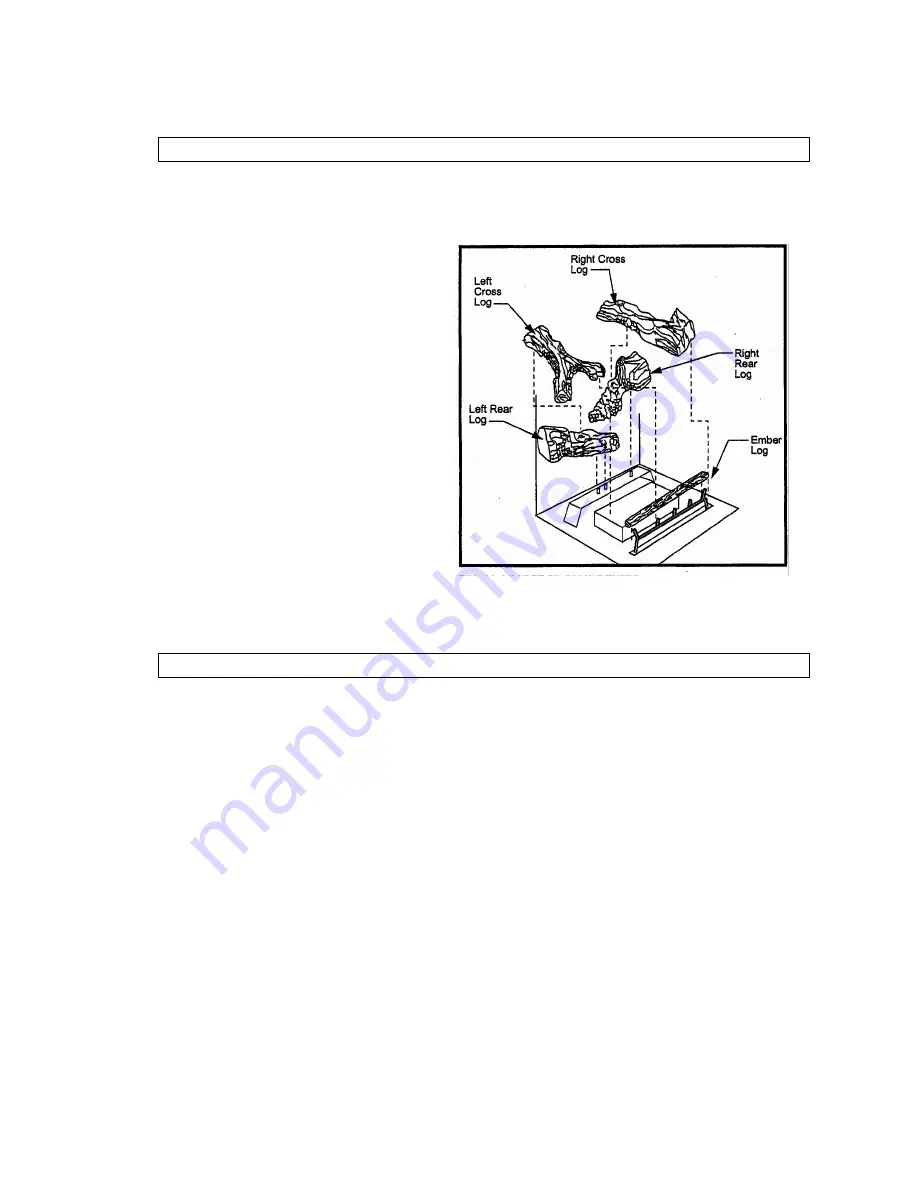

Log Installation

Warning: As with all plastic bags, these bags are not toys and should

always be kept away from children and infants.

1. Remove logs from packaging.

2. Place left rear log on rear

support. Ensure that log is firmly

positioned and there is no side

to side movement. (Refer to

Figure 11)

3.

Carefully place ember log

between grate and burner.

4.

Place the front of right rear log

on the burner and the back of

the log on the rear log support.

5.

Place the top logs onto the

locator notches. Ensure the logs

are secure.

Figure 11

First Firing

Upon completion of the gas fitting line, a small amount of air will be trapped in the

gas pipe. When first lighting the pilot light, it will take a few minutes to purge the

trapped air.

Once purging is complete, the pilot and burner will light and will operate as outlined

in the instruction manual. Subsequent lighting of the appliance will not require

purging.

When lit for the first time, the appliance will emit a slight odour for an hour or two.

This is due to the paint and lubricants used in the manufacturing process.

Page 11 of 18