12

SHR Series Woodburning Fireplace

20001384

Installing the Chimney System

Start by attaching the first chimney section to the collar

on top of the fireplace.

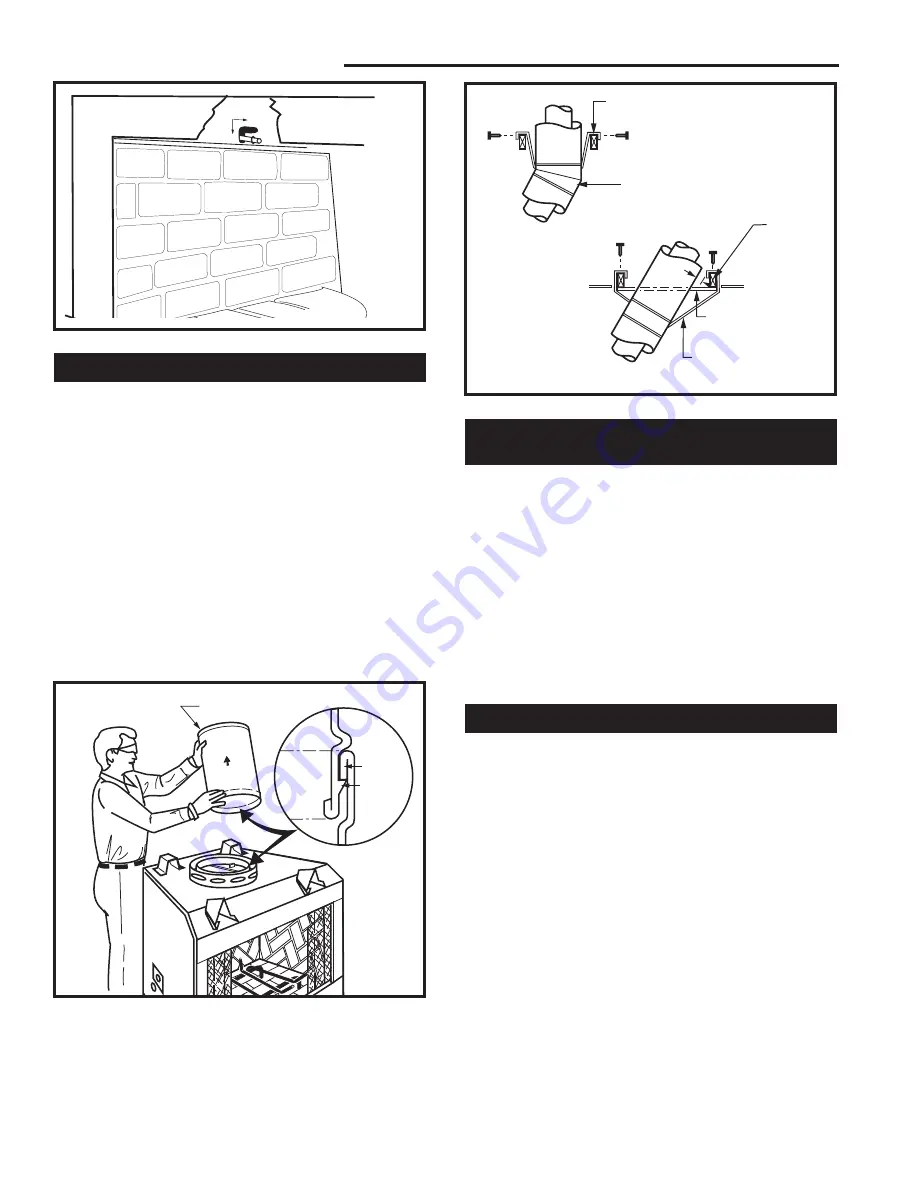

Install the pipe as pictured in Figure 19. When you

get a good lock, you will hear the pipe clearly snap

together. Once sections are snap-locked in place, it is

extremely difficult to get them apart.

Make sure the

pipe is firmly snapped and locked together as each

pipe section is mounted.

When installing elbows, only outer pipe will snap- lock.

Middle pipes simply slide into position. Be sure to

always attach straps on upper elbow to a structural

framing member. (Fig. 20)

Continue installing the pipe as required until pipe is

installed up through the ceiling. At this point, you must

install a firestop spacer.

FP270/271

CR Series

2/19/99 djt

ELBOW STRAP

ANGLED STRAP

Fig. 20

Attach straps to a structural framing member.

FP270/271

Support Structure

Elbow Strap

(must be tight)

Ceiling

Hole

Framing

Angle Firestop

Chimney Support

Strap

(must be tight)

UP

FP558SHR

snap lock

5/11/99 djt

FP558SHR

Fig. 19

Install pipe, listening for the snap-lock to fasten.

Inner Pipe Section

Hem

Lance

Pipe

Rim

Pipe

Rim

FP710a

SHR OUTSIDE AIR LEVER

WOOD FIREPLACES

10/21/99

Closed

Open

Fig. 18

Outside air operation.

FP710a

Installing the Firestop Spacer

in the Ceiling Hole

A firestop spacer is used to keep pipe spaced properly

and required for safety.

Nail the firestop spacer (at each corner) to the framing

members of the ceiling hole.

Note:

A firestop spacer is

not required at the roof.

Hole sizes listed in Figure 14 for angled firestop spac-

ers provide minimum required air space to chimney

pipe for ceiling thickness up to eight (8) inches. When

combined thickness of ceiling material, ceiling joists and

flooring material exceeds eight (8) inches, adjustments

must be made in framing to assure that minimum air

spaces to chimney are maintained.

Proper Firestop Spacer Installation

Figure 21 shows different installation procedures for

both an area that

is

an attic and an area that

is not

an

attic.

If the area above the ceiling

is not

an attic, position the

firestop spacer with the flange on the ceiling side and

the angled portion extending up into the hole.

If the area above the ceiling

is

an attic, position the

firestop spacer with the flange on the top of the framed

hole and the angled portion extending down into the

hole.

Firestop spacers are not available for, nor are they

required on, vertical walls.

The chimney components (CF11) used on the SHR

series fireplaces have been tested and approved with

the area where the outer pipe slides through the firestop

spacer sealed with a noncombustible caulk if desired,

or left completely open with no sealant. This sealing

only applies to the SHR series fireplace.