Summary of Contents for UAM76

Page 2: ......

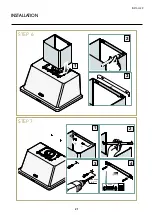

Page 19: ...19 INSTALLER INSTALLATION STEP 2 STEP 3 2 1 OK ...

Page 20: ...20 INSTALLATION STEP 4 STEP 5 1 2 3 2 1 NON FORNITA NOT PROVIDED ø8 mm ø 05 16 NOT PROVIDED ...

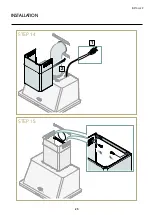

Page 21: ...21 INSTALLER INSTALLATION STEP 6 STEP 7 1 3 4 2 2 3 1 ø8 mm ø 05 16 40 mm 137 64 ...

Page 22: ...22 INSTALLATION STEP 8 STEP 9 ...

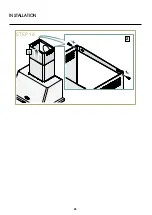

Page 23: ...23 INSTALLER INSTALLATION STEP 10 STEP 11 2 1 150 mm 5 29 32 min 3 2 1 3 4 ...

Page 24: ...24 INSTALLATION STEP 12 STEP 13 2 3 4 1 ø8 mm ø 05 16 40 mm 137 64 ...

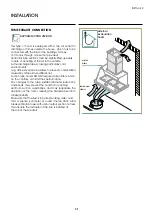

Page 25: ...25 INSTALLER INSTALLATION STEP 14 STEP 15 1 2 ...