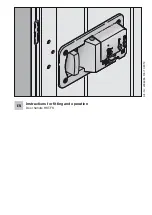

There are three holes inside and outside to drill next. The factory template

calls for a .196 diameter drill bit. Our drill guides will accept a 13/64” twist

drill, a lot easier to find in the field. The bottom holes shown being drilled

on the right is a pilot hole that will be drilled later.

Once the faceplate has been cut out it is time to start drilling the function

holes. Starting at the top, drill the inside and outside holes with a 1-1/4”

hole saw. If retrofitting, drill these holes to clean up any misalignment.